cov khoom siv

Lub thawv tsis haum

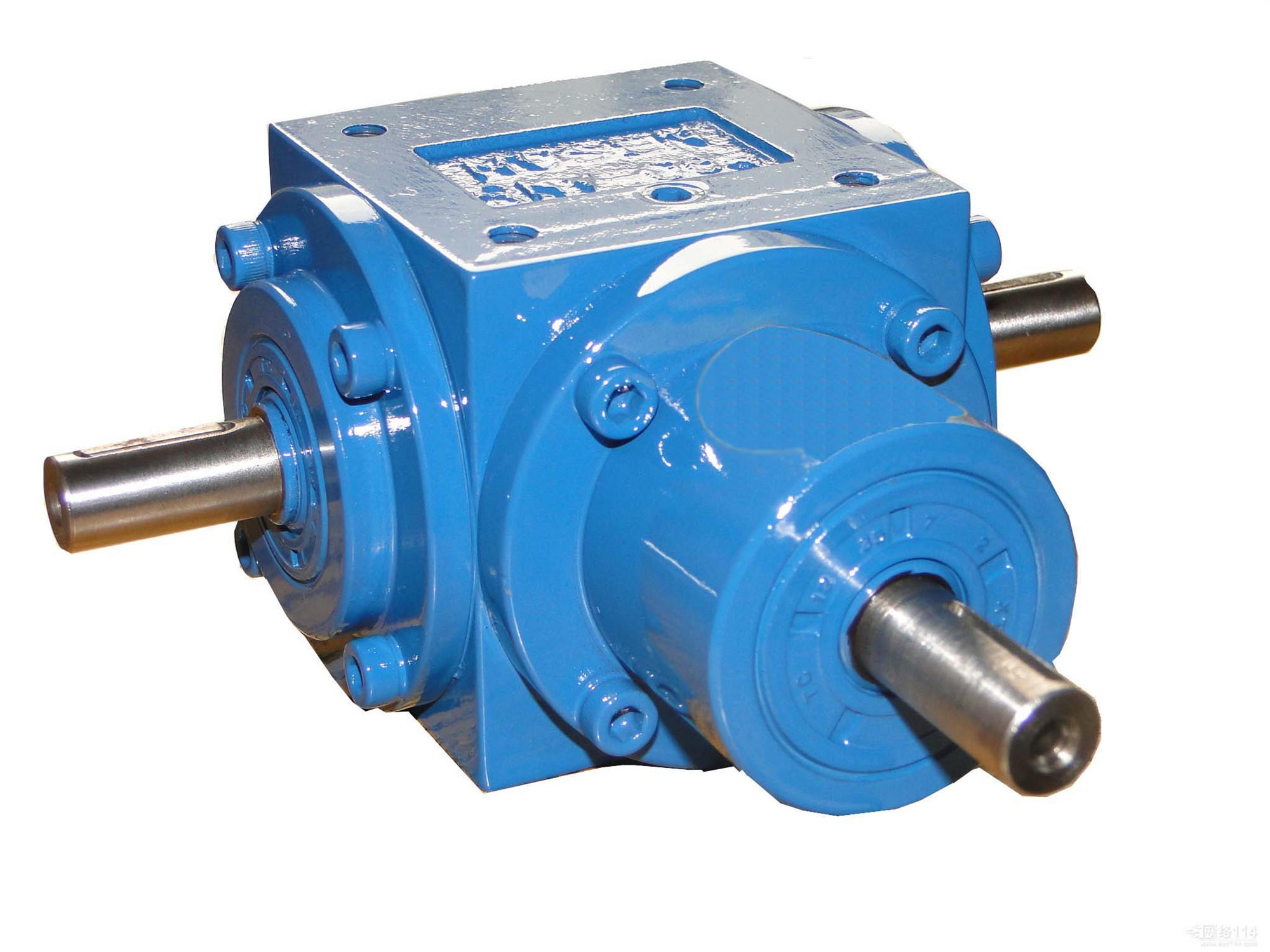

angular gearbox chaw tsim tshuaj paus, txoj cai kaum gearbox, muab kauv iav kauv iav manufacturers

Ib-theem kauv bevel iav kis tau tus mob lub thawv, muaj qauv, muaj ntau yam, sib piv ceev ntawm 1: 1, 1.5: 1, 2.5: 1, 3: 1, 4: 1, 5: 1 yog qhov sib kis ntawm qhov tseeb. Qhov nruab nrab ntawm kev ua hauj lwm yog 98%. Muaj cov axis nkaus xwb, ob chav kab rov tav, ib kab ntsug ib qho, ob chav kab ntsug xaiv tau.

T-hom kauj thawv yog twb dhau los ua khoom lag luam hauv kev lag luam xa khoom hauv lub tebchaws. Txawm tias qee qhov sib kis me me

cov khoom lag luam khoom muaj cov khoom lag luam zoo li qub txuas nrog thawb khoom kab; T-hom lub thawv tsav tau tsim nyob rau hauv

kev lag luam hauv kev lag luam los ntawm cov qauv tsim qauv mus rau kev xaiv tivthaiv. Kev cai paub tab. Lub T-hom kauj thawv yog

nruab nrog ib-kab, ob txoj kab rov tav axis, ib qho ntsug ib qho thiab ob tog ntsug. Nws tuaj yeem yog cov lus sib dhos ib leeg

dual-axis tso tawm lossis dual-axis input ib-axis tso zis ntau lawm, thiab cov kab hluav taws xob kis tau tuaj yeem ua tiav lub hom phiaj

deceleration lossis nce ceev. Lub thawv tsav lub cev yog ua los ntawm ** aluminium alloy, uas muaj ntau yam zoo xws li

zoo nkauj tsos, muaj zog adaptability, zoo tshav kub dissipation kev ua tau zoo, muaj zog nqa lub peev xwm thiab kev pab lub neej ntev.

T-hom kauj thawv muaj ntau txoj kev teeb tsa, adopts hollow output ncej qauv, ntau cov tswv yim thiab tawm qauv,

yooj yim kev sib xyaw nrog lwm cov tshuab, muaj kev hloov kho tau zoo thiab yooj yim kev teeb tsa. Thiab kis tau tus mob yog

ruaj khov, siab ua haujlwm, suab nrov tsawg, nyab xeeb thiab txhim khu kev qha.

Yam khoom ntawv

Form Daim ntawv teeb tsa: puag teeb tsa.

Form Axis configuration daim ntawv: ib qho kev tawm tswv yim ib zaug xwb, ib qho kev tawm tswv yim dual cov zis, cov lus qhia ib qho peb zaug, cov lus tso tawm ib qho.

Tso zis tawm: cov khoom ua haujlwm.

Cov qauv tsim, ntau hom, ceev nrawm 1: 1, 1.5: 1, 2: 1, 3: 1 yog txhua qhov kev sib kis. Thaum lub nrawm nrawm tsis yog 1: 1, cov kab rov tav axis txhawb nqa thiab tso zis ntsug tau txiav txim siab, thiab kab rov tav

kev tawm tswv yim thiab kab rov tav axis cov zis tau nce ceev. Muab kauv bevel iav qauv, kis tau tus mob ruaj khov, suab nrov tsawg, qis kev co thiab muaj peev xwm nqa tau. Muaj nyob rau hauv dual tswv yim ncej daim ntawv. Sha Pom tau ntau cov tes tsho tuaj yeem paub. Tuaj yeem siv rau hauv txhua qhov chaw teeb tsa

Muaj ntau ntau yam ntawm cov qias neeg hauv keeb kwm, tab sis ntau qhov tau raug tshem tawm. Cais raws li daim ntawv ntawm

pab, lub kauj tsheb tuaj yeem muab faib ua cov tshuab (tsis yog pab) thiab hloov kho (siv zog).

Khib thiab pinion lub kauj iav yog qhov yooj yim tshaj plaws ntawm lub kauj. Nws qhov zoo yog cov qauv yooj yim, cov qauv compact, siab

kev siv nruj, tus nqi qis, rhiab kauj, siab zoo thiab thim rov qab nres nres, yooj yim los npaj, thiab tshwj xeeb tshaj yog haum rau siv

nrog lub tswm ciab raug tshem tawm thiab MacPherson kev ncua, thiab kuj tuaj yeem ncaj qha Tus pas nrig siv tau tsav kom yooj yim lub kauj

tshuab. Yog li ntawd, nws tau siv dav hauv tsheb thiab micro thiab lub tsheb thauj khoom me me.

Lub recirculating pob kauj iav muaj qhov zoo thiab tsis zoo rau kev ntaus, yog li nws yog lub teeb hauv kev ua haujlwm, ntev hauv lub neej thiab

ruaj khov thiab txhim khu kev qha hauv kev ua haujlwm; txawm li cas los xij, vim tias qhov txiaj ntsig siab ntawm counterattack, nws yog qhov yooj yim rau kis qhov kev cuam tshuam ntawm txoj kev

nto rau ntawm lub kauj. Lub zog fais fab kauj yog qhov kev sib txuas ntawm cov neeg kho tshuab lub kauj thiab lub pob tsav tsheb. Lub hwj chim kauj

Lub zog fais fab kauj yog qhov kev sib txuas ntawm cov neeg kho tshuab lub kauj thiab lub pob tsav tsheb. Lub hwj chim kauj

Lub zog muaj nyob rau hauv ob qho tib si pneumatic thiab hydraulic qauv nyob ntawm lub zog hloov nruab nrab. Ntawm lawv, cov

hydraulic zog lub zog hwj huam tuaj yeem muab faib ua txhua hom (siv tshuab ntaus lub pob, lub zog lub tog raj kheej thiab

raws li cov kev teeb tsa thiab kev sib txuas ua ke ntawm lub tshuab tsav lub hau, lub hwj huam lub tog raj kheej thiab

lub kauj tswj kev tswj kav hauv lub tshuab nqa khoom). Lub kauj tswj lub pob valve tau tsim raws li ib qho), ib nrab sib xyaw (tsim

cov tshuab qog thiab cov khoom siv tswj cov kauj, cov kav fais fab lub tog raj kheej ywj siab) thiab cais tawm (cov kauj tshuab txhua lub

ywj siab, kauj tswj lub pob valve thiab lub hwj chim lub tog raj kheej) Tsim raws li ib qho) peb hom kev teeb tsa.

Nws yog tsim nyog sau cia tias pneumatically loaded fais lub zog yuav tsum tsis txhob siv cov tsheb thauj khoom hnyav vim lub

ua haujlwm siab ntawm lub tshuab pneumatic yog tsawg (feem ntau tsis siab tshaj 0.7 MPa), thiab qhov loj me ntawm cov khoom siv tau siv

nyob rau hauv lub tsheb thauj khoom hnyav yuav dhau hwv. Kev ua haujlwm siab ntawm qhov hydraulic zog lub zog kauj yuav ua tau siab li 10

MPa lossis ntau dua, yog li ntawd qhov loj ntawm lub Cheebtsam me me. Lub kaw lus hydraulic ua haujlwm tsis muaj suab nrov, muaj lub sijhawm ua haujlwm luv luv lub sijhawm,

thiab nqus cov kev poob siab los ntawm cov chaw uas tsis zoo. Yog li no, txoj hlua hluav taws xob hydraulic lub zog tau siv dav hauv ntau yam

hom tsheb.

T sib zog ua haujlwm cov txheej txheem yog cov qauv, ntau yam, thiab muaj qhov zoo ntawm ib leeg, ob chav kab rov tav, ib leeg

ntsug axis thiab ob npaug rau kev txiav ntsug. Nws yog dav siv hauv metallurgy, mining, petrochemical, haus luam yeeb, ceramics, roj hmab thiab

plastics, grain thiab roj zaub mov, npias thiab dej haus, tsheb thauj mus los thiab kev tsim tawm hauv vaj hauv tsev, peb sab

chaw nres tsheb, kev tiv thaiv ib puag ncig thiab lwm yam kev lag luam. Muab kauv nkhaus iav siv tau rau pem hauv ntej thiab thim rov qab, qis nrawm lossis

kev kub ceev Cov kis tau yooj yim, thiab lub suab qis yog qis, kev vibration yog me me, thiab cov kabmob muaj peev xwm loj. Tus

cov qauv khoom tseem ceeb yog: T2, T4, T6, T7, T8, T10, T12, T16, T20, T25. Qhov ntsuas ceev ntawm 1: 1, 1.5: 1, 2.5: 1, 3: 1, 4: 1, thiab

5: 1 yog qhov yuav suav tseeb. Qhov nruab nrab ntawm kev ua hauj lwm yog 98%. Muaj tib lub axis, ob chav kab rov tav, ib ntsug ib qho

thiab ob npaug rau kab ntsug.

T series kauj iav siv rau kev txo kev sib kis. Lub zog yog ua los ntawm cov hlau tsis tshua muaj hlau thiab cov hniav yaig

yog carburized thiab hardened. Cov koob ntawm cov kauj muaj cov kev pab cuam lub neej ntev, kev sib piv loj ntawm cov tswv yim fais fab thiab cov sib pauv

kev ua haujlwm zoo, ruaj khov ua haujlwm, suab nrov tsawg thiab kev sib kis loj. (nce txog 95% -98%)

T series muab kauv bevel iav tig lub thawv, tseem hu ua T-hom kauj thawv, commutator thiab lub kauj iav, yog qhov tseem ceeb

kis cov khoom rau kev lag luam tshuab. Square lub thawv puab, zoo ntim aluminium alloy die-casting box, zoo nkauj thiab dav. Kev ua tau zoo thiab teeb tsa: Zoo tshaj cua sov ua kom tsis muaj zog thiab nqa tau loj. Qhov kev sib kis tau yog tus, ntsiag to, tsis muaj suab nrov, nyab xeeb, txhim khu kev qha

thiab txuag. Ntau txoj haujlwm ntawm kev teeb tsa, hollow tso tawm tus qauv, thiab ntau hom kev nkag thiab tsim tawm, thiab tuaj yeem ua tau yooj yim

ua ke nrog lwm cov tshuab, thiab muaj muaj zog yoog.

T8 thaum ua lub thawv cov chaw tsim khoom tseem ceeb nta: kauv bevel Angular gearbox txheem universal hom: Nws siv cov lus German kawg tsim los kos duab thiab cov txheej txheem tsim khoom kom paub meej cov

zoo ntawm cov teb chaws Europe, thiab tib lub sijhawm zoo heev luv lub sijhawm xa khoom thiab kev tsim khoom, muab cov neeg siv khoom siab

zoo thiab tus nqi tsawg. Los ntawm lub txee rau cov khoom siv sab hauv, cov qauv kev ua tiav tau zoo heev txo cov hom thiab cov lus nug ntawm cov feem, thiab

zoo heev rau lub sijhawm xa khoom. Nws yog ntau tsim rau specification ntau lawm thiab xaiv ywj. Lub iav yog ua los ntawm cov khoom zoo siab-purity alloy steel 20CrMnTi carburizing thiab quenching, cov hniav saum npoo tawv yog tuaj

rau 60 ± 2HRC, thiab cov hniav hniav sib tsoo precision yog siab txog 5-6. Lub suab nrov tau txo qis thiab lub luag haujlwm thauj khoom ntawm peb lub thawv Angular

yog zoo heev txhim kho. Lub iav iav yog ua los ntawm hnav-resistant alloy tooj dag. Cov cab cab txais tus qauv tsim qauv tshiab thiab siv ua qhov tawv tawv

cov txheej txheem sib tsoo. Qhov kev sib txhuam ntawm cov kis yog ua los ntawm hnav-kev coj tus kheej cov hlau, uas zoo heev txhim kho cov

efficiency thiab lub neej. Cov khoob yog ua los ntawm cov hlau tsis sib haum, thiab cov khoom txheem xws li cov ntsaws ruaj ruaj thiab roj ntsaws ruaj ruaj yog hom thoob ntiaj teb thiab domestic

s. ★ Sib xyaw ua ke siab lub zog casting lub thawv, lub thawv qauv muaj kev coj zoo, yooj yim los txhim kho lub zog ntawm tus ncej thiab

kev coj lub neej, thiab cov qauv tsim ntawm lub npov casting yog qhov yooj yim rau cov kiv cua txias. Aluminium alloy tuag-cam khwb cia vaj tsev, zoo nkauj

tsos, lub teeb yuag, zoo tshav kub dissipation. Cov khoom tuaj yeem raug ua ke nrog ntau yam ntawm lub cev muaj zog, thiab txoj kev teeb tsa tau hloov tau yooj yim thiab siv tau yooj yim.

Iav commutator siv thiab txij nkawm

1. Tom qab cov commutator tau teeb tsa, tshawb xyuas qhov yooj. Rau kev siv nom tswv, thov nqa tawm lub ntsuas tsis muaj thau khoom, thiab zoo li qub

lub lag luam, thauj khoom yog maj mam thauj khoom.

2. Lub commutator yuav tsum tsis txhob siv dhau qhov dhau ntawm theem ntsuas.

3. Lub commutator yuav tsum xyuas seb cov roj qib puas tseem ceeb ua ntej thiab thaum siv. Lub tshuab tau sau nrog

lubricating roj ua ntej tawm hauv lub Hoobkas. Lub npe ntawm cov roj lubricating: nruab nrab load muaj zog iav roj GB5903-86220.

Gear commutator roj pauv qhov system: Cov roj hloov rau thawj zaug Tom qab lub tshuab ua haujlwm tau 300 mus rau 400 teev, cov roj nplua nyeem yuav tsum tau hloov, thiab cov

roj nplua nyeem yuav tsum tau hloov txhua 1500 mus rau 2000 teev. Hauv qhov chaw ua haujlwm nrog kev ua haujlwm hnyav, qhov kub thiab txias

thiab cov hmoov av siab, cov roj nplua nyeem yuav tsum kuaj xyuas txhua ib nrab lub hlis. Nws pom tau tias cov roj nplua nyeem muaj cov av, uas yog,

lubricating roj yog hloov los khaws cia nws. Lubricating roj ntxuav, ua kom ntev lub neej ntawm commutator thiab txhim kho kev lag luam muaj txiaj ntsig. Kev hloov roj Lub commutator yuav tsum tau hloov pauv mus rau hauv lub xeev tsiv, vim hais tias qhov viscosity ntawm cov roj lubricating tom qab txias

nce, thiab nws yog qhov nyuaj rau tawm cov roj. Peb cov Angular gearbox yog lub zog hloov cov tshuab siv lub zog hloov ceev rau decelerate tus naj npawb ntawm revolutions ntawm

lub cev muaj zog (lub cev muaj zog) mus rau qhov yuav tsum muaj ntawm kev hloov kho thiab tau txais kev ua haujlwm nrog lub zog loj. Hauv qhov tam sim no

cov txheej txheem rau kev xa cov fais fab thiab cov lus tsa suab, qhov ntau ntawm kev thov ntawm peb Angular gearbox muaj qhov dav heev. Nws tuaj yeem pom hauv

yuav luag txhua hom kev siv tshuab sib kis, los ntawm nkoj, lub tsheb, lub zog, cov tshuab hnyav rau kev tsim kho,

cov cuab yeej siv thiab cov khoom siv ntau lawm siv cov tshuab kev lag luam, rau lub neej txhua hnub. Tsev

cov cuab yeej siv, lub moos, thiab lwm yam. Nws daim ntawv thov tuaj yeem pom los ntawm kev sib kis ntawm lub zog loj, rau cov khoom me me, lub kaum sab xis

kev kis tau tuaj yeem pom daim ntawv thov ntawm peb lub Angular gearbox, thiab hauv cov ntawv thov kev lag luam, peb Angular gearbox muaj qhov ua haujlwm ntawm deceleration

thiab nce torque. Yog li ntawd, nws yog dav siv nyob rau hauv kev ceev thiab torque hloov khoom siv.

T series muab kauv bevel iav tig lub thawv, tseem hu ua T-hom kauj thawv, commutator thiab lub kauj iav, yog qhov tseem ceeb

kis cov khoom rau kev lag luam tshuab.

Kev ua tau zoo thiab teeb tsa: Zoo tshaj cua sov ua kom tsis muaj zog thiab nqa tau loj. Qhov kev sib kis tau yog tus, ntsiag to, tsis muaj suab nrov, nyab xeeb, txhim khu kev qha

thiab txuag. Ntau txoj haujlwm ntawm kev teeb tsa, hollow tso tawm tus qauv, thiab ntau hom kev nkag thiab tsim tawm, thiab tuaj yeem ua tau yooj yim

ua ke nrog lwm cov tshuab, thiab muaj muaj zog yoog. Siv dav hauv cov tshuab ua khoom noj khoom haus, tshuaj siv tshuab ua tshuab, tshuab woodworking, tshuab ua kom kws tshuaj, kev ua liaj ua teb

kev siv tshuab, cov khoom siv rau textile, cov khoom siv sib tsoo, cov cuab yeej siv kho mob thiab lwm cov khoom lag luam zoo tagnrho uas xav tau deceleration

kis.

Nta: 1. Case: casted nrog lub zog siab-FC-25 cam khwb cia hlau; 2. Iav: Nws yog tsim ntawm qhov zoo thiab siab-purity alloy steel 50CrMnT quenching thiab tempering, uas yog kho los ntawm

carburizing thiab quenching; 3, lub plhaw loj: kev siv cov khoom lag luam zoo high-purity alloy steel 40Cr quenching thiab tempering ua, nrog dai siab

thauj khoom muaj peev xwm. 4. Cov kabmob: nruab nrog cov kabmob uas muaj lub peev xwm hnyav; 5, roj foob: kev siv ntawm cov nplais roj ob lub cev, nrog lub plua plav thiab cov roj to ntau. Cov ntaub ntawv tsis? Muaj peev xwm yuav nruab nrog tib txoj kab rov tav, ob chav kab rov tav, ib sab ntsug ntsug, ob npaug ntsug ntsug ceev ceev: 1: 1, 1.5: 1, 2: 1, 2.5: 1, 3: 1, 4: 1, 5: 1

Cov khoom siv lubrication: Kev siv cov roj lubricating tsim nyog tuaj yeem ua rau lub tshuab kom cov roj teeb tau zoo thiab txhim kho nws txoj haujlwm kev ua haujlwm. 1, kev siv thawj ob lub lis piam lossis 100-200 teev, rau thawj lub sijhawm hnav, tej zaum yuav muaj me ntsis cov hlau coj sib txuas ntawm cov

qhov ob, thov nco ntsoov ntxuav sab hauv, thiab hloov cov roj nplua nyeem tshiab; 2. Thaum siv rau lub sijhawm ntev, hloov cov roj lubricating txhua txhua rau lub hlis - ib xyoos lossis 1000-2000 teev. Cov kev siv ntawm daim ntawv thov: cov tshuab ua khoom noj, tshuaj machinery, woodworking machinery, tshuab tshuaj, ua liaj ua teb

tshuab, khoom siv rau textile, khoom siv sib tsoo, khoom siv kho mob thiab lwm yam lag luam

- Induction

Ib-theem muab kauv iav kis tau tus mob lub thawv adopts tus qauv ntawm tus ncej nkag thiab cov ncej ntau lawm, uas yuav siv tau rau ib-axis thiab cov khoom sib txuam. Cov khoom lag luam cov qauv khoom suav nrog: T2, T4, T6, T7, T8, T10, T12, T16, T20, T25. Qhov tseeb sib kis tau yog 1: 1, 1.5: 1, 2.5: 1, 3: 1, 4: 1, 5: 1. Qhov nruab nrab ntawm kev ua hauj lwm yog 98%. Muaj tib lub axis, ob chav kab rov tav, ib kab ntsug ib ntsug, ob chav kab ntsug ib qho los xaiv.

- feature

Cov plaub hau yog ua los ntawm high-lub zog FC-25 cam khwb cia hlau; qhov ib-theem kauv bevel iav kis lub thawv yog ua los ntawm lub siab zoo thiab siab-purity alloy steel 50CrMnT quenching thiab tempering, thiab yog carburized thiab quenched thiab av; lub hau loj yog ua los ntawm cov qib high-quality high-purity alloy steel 40Cr quenching thiab tempering.

Kev raug tshem tawm siab thiab lub nra hnyav muaj peev xwm; Kabmob: nruab nrog cov kabmob uas muaj lub peev xwm hnyav; Roj foob: Nws adopts coj ob daim di ncauj roj foob, ib-theem kauv bevel iav kis tau tus mob uas muaj tsis tshua muaj neeg dustproof thiab roj to kuj.

Lub T-hom kauj iav tau txais kev pom zoo los ntawm cov neeg siv nrog nws qhov kis tshwj xeeb thiab kev ua haujlwm siab. Tus

lub thawv coj lub cev adopts _ aluminium alloy square box puab, thiab adopts-purity alloy steel 20CrMnTiH carburizing thiab

quenching iav thiab alloy hlau quenching thiab tempering ntxaiv. , cov kabmob uas quav, ob daim di ncauj roj roj foob. Nws muaj ntau

qhov zoo xws li cov tsos zoo nkauj, muaj kev yoog yooj yim, cov cua sov kom zoo zoo, muaj peev xwm nqa tau zoo

thiab kev pabcuam lub neej ntev.

T-hom kauj thawv muaj ntau txoj kev teeb tsa, adopts hollow output ncej qauv, ntau cov tswv yim thiab tawm qauv,

yooj yim kev sib xyaw nrog lwm cov tshuab, muaj kev hloov kho tau zoo thiab yooj yim kev teeb tsa. Thiab kis tau tus mob yog

ruaj khov, siab ua haujlwm, suab nrov tsawg, nyab xeeb thiab txhim khu kev qha.

T-hom kauj kem lub thawv kev tsis sib xws: T-hom kauj thawv fais fab ntau: 0.014kW - 335 kW T-hom kauj thawv lub zog: 11.2Nm - 5713 Nm T-hom lub thawv khawm tuaj yeem nruab nrog cov kab rov tav ib sab, ob chav kab rov tav. , ib sab ntsug ntsug, ob npaug ntsug

axis T-hom txheej txheem lub thawv ceev: 1: 1, 1.5: 1, 2: 1, 2.5: 1, 3: 1, 4: 1, 5: 1 Vaj Tse: kev nruj siab FC-25 cam khwb cia hlau casting; Iav: Cov iav tau ua ntawm _ siab purity alloy tsuas yog 20CrMnTiH carburized thiab quenched, thiab hauv av; Lub ntsiab loj: tus ncej hom adopts alloy tsuas-tempered thiab siab-dai hnyav load; cov kabmob: cov kabmob uas muaj lub nra hnyav; Roj foob: roj foob ntawm ob daim di ncauj ntim, uas muaj ob qho tib si dustproof thiab roj-pov thawj tsis kam;

T-hom lub thawv thaum ua tiav cov yam ntxwv: 1. Lub thawv khawm muaj ib leeg, ob chav kab rov tav, ib qho ntsug thiab ob npaug ntsug axis. 2. Lub thawv kem muaj cov txheej txheem muaj zog thiab ntau ntau yam, thiab tus qauv nrawm yog txhua qhov kev sib kis tiag. Tus

qhov nruab nrab ua hauj lwm zoo yog 98%. 3. Thaum qhov nrawm nrawm tsis yog 1: 1, cov kab rov tav ntawm txoj kab rov tav thiab cov qhov tso zis tawm ntsug yog decelerated, thiab feem ntsug

axis cov ntsiab lus thiab cov kab rov tav axis tso tawm tau nce ceev. 4. Lub thawv tsav T-hom tuaj yeem ua rau pem hauv ntej thiab rov qab cov lus qhia, nrog kev nrawm qis lossis kev sib kis ceev,

suab nrov tsawg, qis kev co thiab siab thev taus.

- Tus Nqi them

Qhov ib-theem kauv bevel iav kis tau tus mob lub thawv, muaj qauv, ntau yam, ceev piv 1: 1, 1.5: 1, 2: 1, 2.5: 1, 3: 1, 4: 1, 5: 1 tag nrho yog cov kis tau tus mob tiag tiag piv. Qhov nruab nrab ntawm kev ua hauj lwm yog 98%.

Cov tsos mob: 1. Qhov xwm txheej: cam nrog lub siab-FC-25 cam khwb cia hlau; 2. Iav: Nws yog tsim ntawm qhov zoo thiab siab-purity alloy steel 50CrMnT quenching thiab tempering, uas yog kho los ntawm

carburizing thiab quenching; 3, ua lub ntsiab: kev siv cov khoom zoo-purity alloy steel 40Cr quenching thiab tempering processing, nrog siab

muaj peev xwm dai load. 4. Cov kabmob: nruab nrog cov kabmob uas muaj lub peev xwm hnyav; 5, roj foob: kev siv ntawm cov nplais roj ob lub cev, nrog lub plua plav thiab cov roj to ntau.

- Qhov tseem ceeb cov txiaj ntsig zoo

T series ib-theem muab kauv iav kis kis tau tus mob lub thawv, muaj qauv, ntau yam, sib txawv ceev 1: 1, 1.5: 1, 2: 1, 2.5: 1, 3: 1, 4: 1, 5: 1 Txhua qhov kis tau tus mob piv. Qhov nruab nrab ntawm kev ua hauj lwm yog 98%. Muaj nyob rau hauv ib qho axis, ob chav kab rov tav, ib ntsug ntsug, thiab ob chav ntsug ntsug.

ib-theem kauv bevel iav kis tau kis lub thawv tuaj yeem ua rau pem hauv ntej thiab rov qab cov lus qhia, nrog kev nrawm lossis qeeb nrawm kis, lub suab qis, qis kev co thiab siab thev taus. Thaum lub nrawm piv tsis yog 1: 1, cov kab rov tav ntawm cov kab rov tav thiab cov khoom qhov tso tawm ntsug tau txiav txim siab, thiab cov ntawv cog lus axis thiab cov kab rov tav ntau qhov nce ceev.

- Tswj

Siv thawj ob lub lis piam lossis 100-200 teev, rau thawj lub sijhawm hnav, tej zaum yuav muaj me ntsis cov hlau coj ntawm ob, thov nco ntsoov ntxuav sab hauv, thiab hloov cov roj av tshiab; kev siv ntev ntev, txhua rau lub hlis - ib xyoos lossis 1000-2000 Hloov cov roj ib zaug ib teev. Qhov tsim nyog lubrication ntawm qib ib-theem kauv bevel iav kis kis tau tus mob tuaj yeem ua rau lub tshuab nqa kom zoo dua thiab txhim kho nws txoj haujlwm.

T-hom cov thawv yog qhov khoom xa tawm tseem ceeb rau kev lag luam xa tshuab. T-hom lub thawv cov khoom siv yog pom zoo los ntawm cov neeg siv nrog cov kis tshwj xeeb thiab cov khoom tsim muaj txiaj ntsig zoo. Lub kauj

lub thawv lub cev adopts zoo aluminium alloy square lub thawv puab, thiab adopts-purity alloy hlau 20CrMnTiH carburized thiab

quenched iav thiab alloy hlau quenching thiab tempering ntxaiv. , cov kabmob uas quav, ob daim di ncauj roj roj foob. Nws muaj ntau

qhov zoo xws li cov tsos zoo nkauj, muaj kev yoog yooj yim, cov cua sov kom zoo zoo, muaj peev xwm nqa tau zoo

thiab kev pabcuam lub neej ntev. T-hom kauj thawv muaj ntau txoj kev teeb tsa, adopts hollow output ncej qauv, ntau yam

cov tswv yim thiab tso zis tawm qauv, kev sib xyaw yooj yim nrog lwm cov tshuab, muaj kev yoog hloov kho thiab yooj yim kev teeb tsa.

Thiab kis tau tus mob ruaj khov, siab ua haujlwm, suab nrov tsawg, muaj kev nyab xeeb thiab txhim khu kev qha.

T-type kauj kem ib leeg-tawm lub rooj tsav ob-axis peb Angular gearbox. Hauv qee cov ntawv thov, vim qhov chaw tsis tshua muaj teeb tsa hauv ib qho

kev taw qhia, muaj cov khoom siv cav ntsia thaum lub sijhawm nws tsis tuaj yeem ntsia ncaj qha rau ntawm lub cuab yeej. Koj yuav tsum xav

nruab qhov qub chaw kom tsawg li sai tau, yog li qhov no, qee cov neeg siv xav txog kev txhim kho kauv los ntawm Angular gearbox lossis cov txo iav

nyob rau hauv daim ntawv ntawm lub kauj nyob ntawm tsav. Lub cev muaj zog

Yog tias koj xav txo lub siab me thiab nce lub zog ntsaws, tom qab ntawd xaiv ob hom hardened gearbox K-hom peb Angular gearbox lossis

S-hom cab kauv kauv bevel Angular gearbox. Yog tias koj tsuas yog xav ua kom txoj haujlwm rov qab, tom qab ntawd xaiv 1: 1. Lub thawv nyob kauj. Cov ntsiab lus ntawm

cov kev siv sib txawv yuav tsum muaj qhov sib txawv.

Qhov kev pabcuam zoo tshaj plaws los ntawm peb tus kws tsav tsheb xa mus rau koj lub inbox ncaj qha.

peb pab

Tau Txais

Yantai Bonway Manufacturer Co. Ltd

ANo.160 Changjiang Road, Yantai, Shandong, Suav teb (264006)

T + 86 535 6330966

W + 86 185 63806647