Siab siab torque txoj cai kaum lub thawv

siab siab torque txoj cai kaum lub zog gearbox, siab rpm txoj cai kaum sab xis lub thawv, siab ceev txoj cai kaum lub thawv, muaj kev kub ceev txog 90 degree gearbox, ua haujlwm siab lub zog

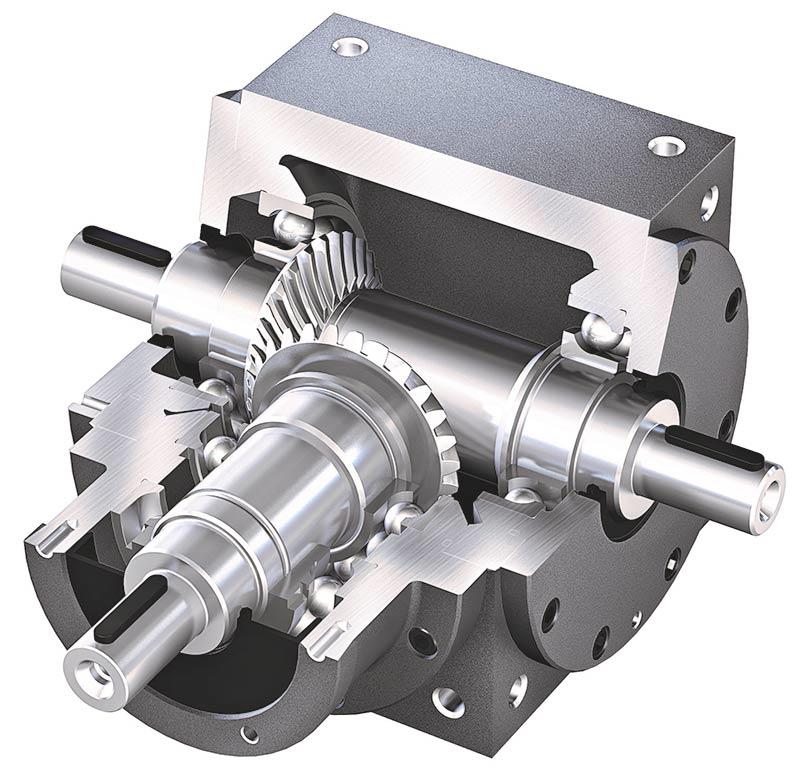

Ib-theem kauv bevel iav kis tau tus mob lub thawv, muaj qauv, muaj ntau yam, sib piv ceev ntawm 1: 1, 1.5: 1, 2.5: 1, 3: 1, 4: 1, 5: 1 yog qhov sib kis ntawm qhov tseeb. Qhov nruab nrab ntawm kev ua hauj lwm yog 98%. Muaj cov axis nkaus xwb, ob chav kab rov tav, ib kab ntsug ib qho, ob chav kab ntsug xaiv tau.

Taw qhia: Nws tuaj yeem ua haujlwm txuas mus rau tom ntej thiab rov qab, nrog lub nrawm lossis lub nrawm kis tau tus mob, lub suab qis, thiab tsis tshua muaj kev vibration. Peb lub tswv yim kev lag luam yog ua raws cov ntawv thov cov khoom lag luam thiab kev pabcuam zoo siab. Cov cuab yeej siv qib siab thiab kev tswj hwm tshiab, thiab lub hauv paus tsim khoom lag luam muaj zog tau tso lub hauv paus zoo rau kev koom tes nrog peb cov neeg siv khoom.

T series thawj-theem muab kauv iav kauv iav kem iav, txheem txheej, ntau yam, nrawm nrawm txo 1: 1, 1.5: 1, 2: 1, 2.5: 1, 3: 1 yog

tag nrho cov nqi sib kis, nrog cov kab rov tav ib sab thiab ob chav kab rov tav, ib ntsug ntsug, ob sab ntsug ntsug

xaiv

Cov yam ntxwv ntawm kev ua tau zoo: 1, T series muab kauv bevel iav tig kauj kem, txheem txheej, ntau hom, ceev nrawm yog txhua qhov tseeb sib kis. Tus

qhov nruab nrab ua hauj lwm zoo yog 98%. 2. Cov muab kauv kauv iav kauv kem lub thawv muaj ib tus ncej tib, ob chav kab rov tav, ncej ib feem ntsug thiab ob chav ncej. 3. Lub thawv tsav iav tuaj yeem ua haujlwm rau pem hauv ntej thiab thim rov qab, nrog lub nrawm lossis siab ceev kis, qis

suab nrov, tsis tshua muaj kev vibration thiab siab thev taus ntev. 4. Thaum lub nrawm nrawm tsis yog 1: 1, qhov tso tawm kab rov tav thiab cov qhov tso zis tawm ntsug yog decelerated, thiab feem ntsug

axis cov ntsiab lus thiab cov kab rov tav axis tso tawm tau nce ceev. 5. Lub thawv tsav iav tuaj yeem ua haujlwm rau pem hauv ntej thiab thim rov qab, nrog lub nrawm lossis siab ceev kis, qis

suab nrov thiab tsis tshua muaj kev co.

Cov yam ntxwv ntawm T T tshooj tig lub thawv, nqa tau nrawm dua ntawm WB series cycloid reducer thiab lub hau ntswj

nqa, thiab cov kabmob muaj peev xwm. Cov duab ntawm T-series kauj lub thawv yog lub cev zoo, uas tuaj yeem siv rau kev sib txawv. Nws yog dav

siv rau hauv cov tshuab ua khoom noj khoom haus, tshuaj machinery, tshuab ua woodworking, tshuaj tshuab, tshuab ua liaj ua teb,

cov khoom siv rau textile, cov khoom siv sib tsoo, khoom siv kho mob thiab lwm yam lag luam.

cov khoom lag luam: 1. Qhov xwm txheej: cam nrog lub zog siab-FC-25 cam khwb cia hlau; 2. Iav: Nws yog tsim ntawm qhov zoo thiab siab-purity alloy steel 50CrMnT quenching thiab tempering, uas yog kho los ntawm

carburizing thiab quenching; 3, lub plhaw loj: kev siv cov khoom lag luam zoo high-purity alloy steel 40Cr quenching thiab tempering ua, nrog dai siab

thauj khoom muaj peev xwm. 4. Cov kabmob: nruab nrog cov kabmob uas muaj lub peev xwm hnyav; 5, roj foob: kev siv ntawm cov nplais roj ob lub cev, nrog lub plua plav thiab cov roj to ntau.

cov lus qhia kev ntsuas: qhov nra nra piv ntau: 1: 1 1.5: 1 2: 1 2.5: 1 3: 1 4: 1 5: 1 Torque ntau: 11.2 - 5713 Nm Ntau zog: 0.014 - 335 kW

Cov kev ceev faj ua ntej kev teeb tsa: 1. Lub thawv khawm yuav tsum tau muab ntxuav kom huv ua ntej siv, thiab lub thawv ncej yuav tsum tau kuaj xyuas qhov puas thiab av. Yog tias nws yog, nws

yuav tsum muab ntxuav kom huv. 2. Kev khiav hauj lwm kub ntawm lub thawv kauj yog 0 ~ 40 ° C. 3. Kuaj xyuas yog tias qhov sib txuam loj ntawm lub qhov txuas nrog lub thawv khawm ua tau raws li qhov xav tau. Lub siab kam rau ntawm lub qhov

yuav tsum tau H7. 4. Ua ntej siv, hloov qhov txhaws ntawm qhov chaw siab tshaj plaws nrog lub ntsuas pa kom lub nrig kom paub meej tias cov pa hauv lub cev

pom thaum lub thawv yog khiav.

Kev teeb tsa thiab txij nkawm: 1. Lub thawv thev tsuas tuaj yeem raug ntsia rau ntawm lub tiaj tiaj, lub zog-nqus, txhawb kev tiv thaiv torsion-tiv thaiv kev teeb tsa. 2. Nyob hauv tsis muaj xwm txheej dab tsi yuav tsum rauj, txuas, pinion lossis sprocket raug rau hauv cov ncej tsim tawm nrog

rauj, uas yuav ua kev puas rau tus kabmob thiab tus ncej. 3. Tom qab tsim lub thawv kauj, xyuas seb nws puas hloov tau. Rau kev siv nom tswv, thov nqa tawm lub ntsuas tsis thauj khoom. Yog tias lub lag luam

dab tsi, ces maj mam thauj cov haujlwm. 4. Lub thawv tsav yuav tsum tsis txhob siv dhau qhov dhau ntawm kev ntaus nqi. 5. Lub thawv khawm yuav tsum xyuas seb cov roj qib puas tseem ceeb ua ntej thiab thaum siv.

Khiav: 1. Siv thawj zaug yog ob lub lis piam lossis 100-200 teev. Nws yog thawj zaug kev sib txhuam. Tej zaum yuav muaj kev sib txhuam me ntsis hlau ntawm

tus ob. Thov ntxuav sab hauv thiab hloov nrog cov tshiab. 2. Thaum siv rau lub sijhawm ntev, hloov cov roj lubricating txhua txhua rau lub hlis mus rau ib xyoos lossis 1000-2000 teev. 3. Lub hau twj tso kua mis lubricating roj adopts 90-120 degree daim ntawv qhia txog roj puv ntawm Tuam Tshoj National Petroleum Corporation. Tus

kev ua haujlwm qis-nrawm thiab lub teeb-thauj khoom pom zoo. Nws raug nquahu kom siv cov roj puv av roj 90 degrees, nra hnyav

thiab siab kub. Nws raug nquahu kom siv cov roj puv cov roj 120 degrees.

cov lus piav qhia khoom: lub thawv rau kauj, tseem hu ua lub commutator thiab lub kauj tsheb, yog lub zog xa hluav taws xob thiab yog ib qho series

nyob rau hauv lub tshuab xa xov nrawm dua, uas muaj ntau ntawm cov kev siv rau hauv qhov chaw tsim khoom lag luam. Lub thawv kauj tau tiav tiav

standardization thiab kev txawv ntawm cov specifications. Lub thawv khawm muaj ib txoj kab sib dhos, ob txoj kab rov tav ob txoj kab, ib qho ib leeg

cov kab ntsug, thiab ob chav kab ntsug yog xaiv tau. Qhov ntsuas ceev yog 1: 1, 1.5: 1, 2: 1, 2.5: 1, 3: 1, 4: 1, thiab 5: 1 yog txhua qhov tseeb

kis sib piv. Lub thawv tso tawm tuaj yeem ua haujlwm nyob rau hauv ob qho tib si rov tom qab thiab thim rov qab, nrog kev ceev lossis siab nrawm

kis. Thaum cov kauj iav piv tsis yog 1: 1, cov kab rov tav axis cov tswv yim thiab cov khoom tso zis ntsug tau txiav txim siab,

thiab cov ntsiab lus txhawb nqa txoj kab ntsug thiab cov kab rov tav kab tsim tau nce zuj zus.

Kev xa tawm ntawm ib sab: kev siv fais fab tuag rau lub sijhawm ntev ua kom cov kab rov tav khiav tau yooj yim khiav ceev. Nqa cov khoom siv: 1 txo cov zis tawm sab laug thiab sab xis, tom qab tig mus, tib lub sijhawm nqa lub chaw nres tsheb 1 seem: ib qho rov qab tsav sab laug thiab sab nraub qaum los ua kom khiav synchronously Chaw Ua Si Chaw Ua Si: 2 ntsug cov tswv yim, XNUMX kab rov tav ua haujlwm sab nraud txoj haujlwm

Cov yam ntxwv ntawm kev ua haujlwm ntawm lub thawv lub thawv bevel iav: 1, T series muab kauv bevel iav tig lub thawv, txheem txheej txheem, ntau yam, ceev nrawm yog txhua qhov kev sib kis. Tus

qhov nruab nrab ua hauj lwm zoo yog 98%. 2, nws muaj tib lub axis, ob chav kab rov tav, ib txoj kab ncaj nraim, ob chav kab ntsug xaiv tau. 3. Cov kauv qhov khoob khoob khoob khoob khawm muaj peev xwm ua haujlwm nyob rau tom ntej thiab rov qab cov lus qhia, nrog kev nrawm qis lossis kev kub ceev kis tau thiab

uas tsis muaj suab nrov. Kev vibration yog me me thiab cov kabmob muaj peev xwm loj. 4. Thaum qhov ntsuas ceev tsis yog 1: 1, cov kab rov tav axis txhawb nqa thiab tso zis ntsuas ntsug tau txiav txim siab. Lub cim ntsug

kev tawm tswv yim thiab cov kab rov tav axis tso zis tau nce ceev.

Cov yam ntxwv ua haujlwm ntawm lub thawv lub thawv helical iav: 1, muaj tib lub axis, ob chav kab rov tav, ib qho ntsug ib sab, ob chav kab ntsug xaiv tau. 2. Kauv cov iav bevel yuav tuaj yeem ua haujlwm txuas mus rau tom ntej thiab rov qab, nrog lub nrawm lossis siab nrawm kis, lub suab qis

, tsis tshua muaj kev vibration thiab siab thev taus ntev. 3. Thaum lub nrawm nrawm tsis yog 1: 1, qhov tso tawm kab rov tav ntsug thiab qhov tso zis ntsug tau txiav txim siab, thiab txoj kab ntsuas ntsug

kev tawm tswv yim thiab kab rov tav axis cov zis tau nce ceev. 4, ARA series kauv bevel iav kauj npog lub thawv nta: me, txhua yam puag ncig nruab, lub teeb yuag, alloy txhuas plhaub, tus ncej.

yuav tsum siv cov tshuaj tiv thaiv corrosion thaum xaj. Cov roj nplua nyeem tau ntxiv tom qab lub hoobkas.

T series helical iav daim iav tig lub thawv ua cov yam ntxwv: 1. Cov Ntaub Ntawv: casted nrog lub zog siab-FC-25 cam khwb cia hlau; 2. Iav: Nws yog tsim los ntawm cov khoom zoo thiab siab purity alloy steel 50CrMnT quenching thiab tempering, uas yog kho los ntawm

carburizing thiab quenching; 3, ua lub ntsiab: kev siv cov khoom zoo thiab siab purity alloy steel 40Cr quenching thiab tempering processing, nrog siab

peev xwm thauj khoom; 4. Cov kabmob: nruab nrog cov kabmob uas muaj lub peev xwm hnyav; 5. roj foob: Nws adopts coj ob daim di ncauj roj foob thiab muaj lub siab plua plav thiab roj to kuj.

Lub thawv tsav, tseem hu ua lub commutator thiab lub kauj tsheb, yog lub zog xa hluav taws xob thiab yog ib qho series

nyob rau hauv lub tshuab xa xov nrawm dua, uas muaj ntau ntawm cov kev siv rau hauv qhov chaw tsim khoom lag luam. Lub thawv kauj tau tiav tiav

standardization thiab kev txawv ntawm cov specifications. Lub thawv khawm muaj ib txoj kab sib dhos, ob txoj kab rov tav ob txoj kab, ib qho ib leeg

cov kab ntsug, thiab ob chav kab ntsug yog xaiv tau. Qhov ntsuas ceev yog 1: 1, 1.5: 1, 2: 1, 2.5: 1, 3: 1, 4: 1, thiab 5: 1 yog txhua qhov tseeb

kis sib piv. Lub thawv tso tawm tuaj yeem ua haujlwm nyob rau hauv ob qho tib si rov tom qab thiab thim rov qab, nrog kev ceev lossis siab nrawm

kis. Thaum cov kauj iav piv tsis yog 1: 1, cov kab rov tav axis cov tswv yim thiab cov khoom tso zis ntsug tau txiav txim siab,

thiab cov ntsiab lus txhawb nqa txoj kab ntsug thiab cov kab rov tav kab tsim tau nce zuj zus.

Siv thiab txij nkawm / cov thawv tswj a. Kuaj xyuas tias lub thawv ntim yoog raws tau hloov tau tom qab kev teeb tsa. Rau kev siv nom tswv, thov nqa tawm lub ntsuas tsis thauj khoom. Yog tias lub lag luam

dab tsi, ces maj mam thauj cov haujlwm. b. Lub hau thawv yuav tsum tsis txhob siv dhau dhau ntawm cov ntsuas cov pev. c. Lub kauj yuav tsum kuaj xyuas kom paub tseeb roj kom zoo ua ntej thiab thaum siv. Nta: ◆ Txheeb xyuas, ntau hom, sib txawv nrawm ceev 1: 1, 1.5: 1, 2: 1, 3: 1 yog txhua qhov kev sib kis. Thaum lub nrawm nrawm tsis yog 1: 1, cov kab rov tav axis txhawb nqa thiab tso zis ntsug tau txiav txim siab, thiab kab rov tav

kev tawm tswv yim thiab kab rov tav axis cov zis tau nce ceev. Muab kauv bevel iav qauv, kis tau tus mob ruaj khov, suab nrov tsawg, qis kev co thiab muaj peev xwm nqa tau. Muaj nyob rau hauv dual tswv yim ncej daim ntawv. Sha Pom tau ntau cov tes tsho tuaj yeem paub. ◆ Txhua qhov chaw teeb tsa tau siv. Cov khoom lag luam ◆ daim ntawv teeb tsa: lub hauv paus kev teeb tsa. Form Axis configuration daim ntawv: ib qho kev tawm tswv yim ib zaug xwb, ib qho kev tawm tswv yim dual cov zis, cov lus qhia ib qho peb zaug, cov lus qhia ib zaug

tsim tawm. Tso zis tawm: cov khoom ua haujlwm.

- Induction

Ib-theem muab kauv iav kis tau tus mob lub thawv adopts tus qauv ntawm tus ncej nkag thiab cov ncej ntau lawm, uas yuav siv tau rau ib-axis thiab cov khoom sib txuam. Cov khoom lag luam cov qauv khoom suav nrog: T2, T4, T6, T7, T8, T10, T12, T16, T20, T25. Qhov tseeb sib kis tau yog 1: 1, 1.5: 1, 2.5: 1, 3: 1, 4: 1, 5: 1. Qhov nruab nrab ntawm kev ua hauj lwm yog 98%. Muaj tib lub axis, ob chav kab rov tav, ib kab ntsug ib ntsug, ob chav kab ntsug ib qho los xaiv.

T-hom lub thawv cov khoom siv yog pom zoo los ntawm cov neeg siv nrog cov kis tshwj xeeb thiab cov khoom tsim muaj txiaj ntsig zoo. Lub kauj

lub thawv lub cev adopts zoo aluminium alloy square lub thawv puab, thiab adopts-purity alloy hlau 20CrMnTiH carburized thiab

quenched iav thiab alloy hlau quenching thiab tempering ntxaiv. , cov kabmob uas quav, ob daim di ncauj roj roj foob. Nws muaj ntau

qhov zoo xws li cov tsos zoo nkauj, muaj kev yoog yooj yim, cov cua sov kom zoo zoo, muaj peev xwm nqa tau zoo

thiab kev pabcuam lub neej ntev.

T-hom kauj thawv muaj ntau txoj kev teeb tsa, adopts hollow output ncej qauv, ntau cov tswv yim thiab tawm qauv,

yooj yim kev sib xyaw nrog lwm cov tshuab, muaj kev hloov kho tau zoo thiab yooj yim kev teeb tsa. Thiab kis tau tus mob yog

ruaj khov, siab ua haujlwm, suab nrov tsawg, nyab xeeb thiab txhim khu kev qha.

T-hom lub thawv q tuaj yeem tuaj yeem nrog cov kab rov tav ib sab, ob chav kab rov tav, ib ntsug ntsug, ob chav ntsug

axis T-hom kauj thawv ceev piv: 1: 1, 1.5: 1, 2: 1, 2.5: 1, 3: 1, 4: 1, 5: 1

T-hom lub thawv thaum ua haujlwm cov yam ntxwv: 1. Lub thawv khawm muaj ib leeg, ob chav kab rov tav, ib qho ntsug thiab ob npaug ntsug axis. 2. Lub thawv kem muaj cov txheej txheem muaj zog thiab ntau ntau yam, thiab tus qauv nrawm yog txhua qhov kev sib kis tiag. Tus

qhov nruab nrab ua hauj lwm zoo yog 98%. 3. Thaum qhov ntsuas ceev tsis yog 1: 1, cov kab rov tav kab rov tav thiab cov qhov tso zis tawm ntsug yog decelerated, thiab feem ntsug

axis cov ntsiab lus thiab cov kab rov tav axis tso tawm tau nce ceev. 4. Lub thawv tsav T-hom tuaj yeem ua rau pem hauv ntej thiab rov qab cov lus qhia, nrog kev ceev ceev lossis siab ceev kis,

suab nrov tsawg, qis kev co thiab siab thev taus. Mechanical lubrication: Kev siv cov roj lubricating tsim nyog tuaj yeem ua kom tiav cov txiaj ntsig ntawm lub thawv khawm thiab nce nws txoj haujlwm

lub neej.

Cov kev siv ntawm daim ntawv thov: cov tshuab ua khoom noj, tshuaj machinery, woodworking machinery, tshuab tshuaj, ua liaj ua teb

tshuab, khoom siv rau textile, khoom siv sib tsoo, khoom siv kho mob thiab lwm yam lag luam.

HD kauv bevel commutator nta:

1. Cov duab ntawm HD kauv bevel iav commutator yog lub sijhawm tsis tu ncua hexahedron, tuaj yeem hloov mus rau ntau qhov sib txawv.

2. Lub kauv kauv sib luag muaj lub neej ntev kev pab cuam, lub peev xwm loj nqa thiab kev sib kis ruaj khov. Qhov uas tsis muaj kab nrov

yuav tsum txog li 40 m / s, thiab qhov kev sib kis yog li ntawm 94% txog 98%.

3. cov muab kauv-toothed iav iav adopts zoo-carbon tsawg qauv hlau, uas yog raug carburizing thiab

quenching kho cua sov, thiab hauv av thiab ua ke kom ua tiav high precision nyuaj-toothed kaw-hom kis tau tus mob.

4, HD series commutator muaj tag nrho ntawm xya qhov kev qhia tshwj xeeb, kev xaiv loj, cov khoom tawg ua haujlwm nyob rau ntau hom, kom tau raws li

kev xav tau ntawm ntau lub sijhawm.

5. Lub commutator tuaj yeem paub ob hom kev sib kis: kev tshem tawm thiab nce ceev.

Taw qhia: Lub iav reducer feem ntau yog siv rau cov khoom siv sib kis nrog ceev ceev thiab siab siab. Cov txo qis dua qub

ntawm lub cev muaj zog tseem yuav muaj ob peb khub ntawm cov sib zog sib luag kom ua tiav cov nyhuv yam xav tau. Qhov sib piv ntawm cov naj npawb

ntawm cov hniav ntawm cov loj loj thiab me me yog qhov sib piv kis. Nrog cov kev txhim kho tsis tu ncua ntawm kev lag luam reducer,

ntau thiab ntau qhov chaw lag luam tau thov rau tus txo qis.

Iav reducer: 1. R series coaxial helical iav reducer yog tsim raws li thoob ntiaj teb cov kev cai. Nws muaj qib siab

cov ntsiab lus kawm

2. Chaw txuag, txhim khu kev qha thiab ruaj khov, nrog lub siab overload muaj peev xwm thiab hwj chim siab txog 132KW.

3. Kev siv hluav taws xob tsawg thiab kev ua haujlwm zoo. Kev txo qis kom tsawg dua li 95%;

4, tsis tshua muaj kev vibration, tsis tshua muaj suab nrov, txuag lub zog loj;

5, cov khoom lag luam zoo forged steel, hlau nrum hlau box, iav nto tom qab high-frequency tshav kub kho;

6, precision machining kom ua tau kev sib txig sib luag Thiab muab tso rau cov kabmob yuav tsum tau ua, lub ntsuas hluav taws xob uas ua rau helical

iav kis lub rooj sib txoos yog nruab nrog ntau yam kev ua kom lub zog, ua ke rau hauv mechatronics, lav tag nrho lub

cov yam ntxwv zoo ntawm cov khoom.

kev ua tau zoo: 1. Lub iav yog ua los ntawm high-zoo alloy steel rau carburizing thiab quenching. Lub hardness ntawm tus hniav nto yog li 60 ± 2

hrc, thiab qhov raug ntawm cov hniav sib tsoo tau txog siab txog 5-6. 2, siv khoos phis tawm ntawm kev hloov kho tshuab, ua ntej kho kom zoo rau lub iav, zoo heev txhim kho lub peev xwm ntawm lub tshuab reducer. 3, los ntawm lub thawv rau lub thawv rau sab hauv, siv qauv qauv tsim kom tiav, tsim nyog rau kev tsim khoom loj thiab

xaiv yooj. 4. Tus qauv ntsuas hluav taws xob ua qauv tau muab faib raws li daim ntawv nqig zog, uas zam cov hwj huam piv nrog

txoj cai sib luag. 5, siv cad / cam tsim thiab tsim khoom siv los xyuas kom meej qhov ruaj khov ntawm zoo. 6, siv ntau yam ntawm cov qauv sib khi los tiv thaiv roj to. 7, ntau qhov kev taw qhia suab txo kev ntsuas kom ntseeg tau tias lub suab zoo ua tau zoo ntawm lub reducer.

Rau cov teeb meem to, cov txheej txheem ib txwm yuav tsum rhuav thiab qhib lub ntsuas hluav taws xob, hloov lub sealing gasket lossis

thov lub foob, uas tsis yog tsuas yog siv sijhawm ntev thiab siv zog xwb, tab sis kuj tseem nyuaj ua kom muaj kev sib khi zoo, thiab xau dej

yuav tshwm sim dua lub sijhawm ua haujlwm. Cov khoom siv polymer tuaj yeem siv los kho txau rau ntawm qhov chaw. Cov khoom siv muaj zoo heev

kev nplaum, roj tsis kam thiab 350% elongation, uas kov yeej qhov kev cuam tshuam los ntawm kev co ntawm lub tshuab reducer, thiab

daws cov teeb meem ntawm kev txeej ntawm cov ntsuas hluav taws xob rau cov lag luam.

Rau cov teeb meem coj, cov kev daws teeb meem ib txwm ntawm cov neeg ua haujlwm yog kho tom qab kho vuam lossis txhuam plating, tab sis ob qho tib si

muaj qee yam tsis zoo: qhov kev ntxhov siab thermal tsim los ntawm kev kho cov vuam hluav taws xob kub tsis tuaj yeem ua tiav

tshem tawm, uas tuaj yeem ua kev puas tsuaj rau cov khoom siv thiab ua rau cov seem khoov los yog tawg; Kev txhuam hniav plating yog txwv los ntawm qhov

tuab ntawm txheej, thiab nws yooj yim rau tev tawm. Qhov saum toj ob txoj hauv kev siv hlau los kho cov hlau, uas tsis tuaj yeem

hloov txoj kev sib koom tes "nyuaj rau nyuaj". Hauv qab qhov kev txiav txim siab ntawm txhua tus quab yuam, nws tseem yuav ua rau rov hnav.

- feature

Cov plaub hau yog ua los ntawm high-lub zog FC-25 cam khwb cia hlau; qhov ib-theem kauv bevel iav kis lub thawv yog ua los ntawm lub siab zoo thiab siab-purity alloy steel 50CrMnT quenching thiab tempering, thiab yog carburized thiab quenched thiab av; lub hau loj yog ua los ntawm cov qib high-quality high-purity alloy steel 40Cr quenching thiab tempering.

Kev raug tshem tawm siab thiab lub nra hnyav muaj peev xwm; Kabmob: nruab nrog cov kabmob uas muaj lub peev xwm hnyav; Roj foob: Nws adopts coj ob daim di ncauj roj foob, ib-theem kauv bevel iav kis tau tus mob uas muaj tsis tshua muaj neeg dustproof thiab roj to kuj.

- Tus Nqi them

Qhov ib-theem kauv bevel iav kis tau tus mob lub thawv, muaj qauv, ntau yam, ceev piv 1: 1, 1.5: 1, 2: 1, 2.5: 1, 3: 1, 4: 1, 5: 1 tag nrho yog cov kis tau tus mob tiag tiag piv. Qhov nruab nrab ntawm kev ua hauj lwm yog 98%.

- Qhov tseem ceeb cov txiaj ntsig zoo

T series ib-theem muab kauv iav kis kis tau tus mob lub thawv, muaj qauv, ntau yam, sib txawv ceev 1: 1, 1.5: 1, 2: 1, 2.5: 1, 3: 1, 4: 1, 5: 1 Txhua qhov kis tau tus mob piv. Qhov nruab nrab ntawm kev ua hauj lwm yog 98%. Muaj nyob rau hauv ib qho axis, ob chav kab rov tav, ib ntsug ntsug, thiab ob chav ntsug ntsug.

ib-theem kauv bevel iav kis tau kis lub thawv tuaj yeem ua rau pem hauv ntej thiab rov qab cov lus qhia, nrog kev nrawm lossis qeeb nrawm kis, lub suab qis, qis kev co thiab siab thev taus. Thaum lub nrawm piv tsis yog 1: 1, cov kab rov tav ntawm cov kab rov tav thiab cov khoom qhov tso tawm ntsug tau txiav txim siab, thiab cov ntawv cog lus axis thiab cov kab rov tav ntau qhov nce ceev.

- Tswj

Siv thawj ob lub lis piam lossis 100-200 teev, rau thawj lub sijhawm hnav, tej zaum yuav muaj me ntsis cov hlau coj ntawm ob, thov nco ntsoov ntxuav sab hauv, thiab hloov cov roj av tshiab; kev siv ntev ntev, txhua rau lub hlis - ib xyoos lossis 1000-2000 Hloov cov roj ib zaug ib teev. Qhov tsim nyog lubrication ntawm qib ib-theem kauv bevel iav kis kis tau tus mob tuaj yeem ua rau lub tshuab nqa kom zoo dua thiab txhim kho nws txoj haujlwm.

Qhov kev pabcuam zoo tshaj plaws los ntawm peb tus kws tsav tsheb xa mus rau koj lub inbox ncaj qha.

peb pab

Tau Txais

Yantai Bonway Manufacturer Co. Ltd

ANo.160 Changjiang Road, Yantai, Shandong, Suav teb (264006)

T + 86 535 6330966

W + 86 185 63806647