Yas extruder Gearbox

Yas extruder Gearbox, extruder gearbox manufacturers, extruder gearbox rau muag, extruder gearbox kho, sterling extruder gearbox, ntxaib ntsia hlau extruder gearbox

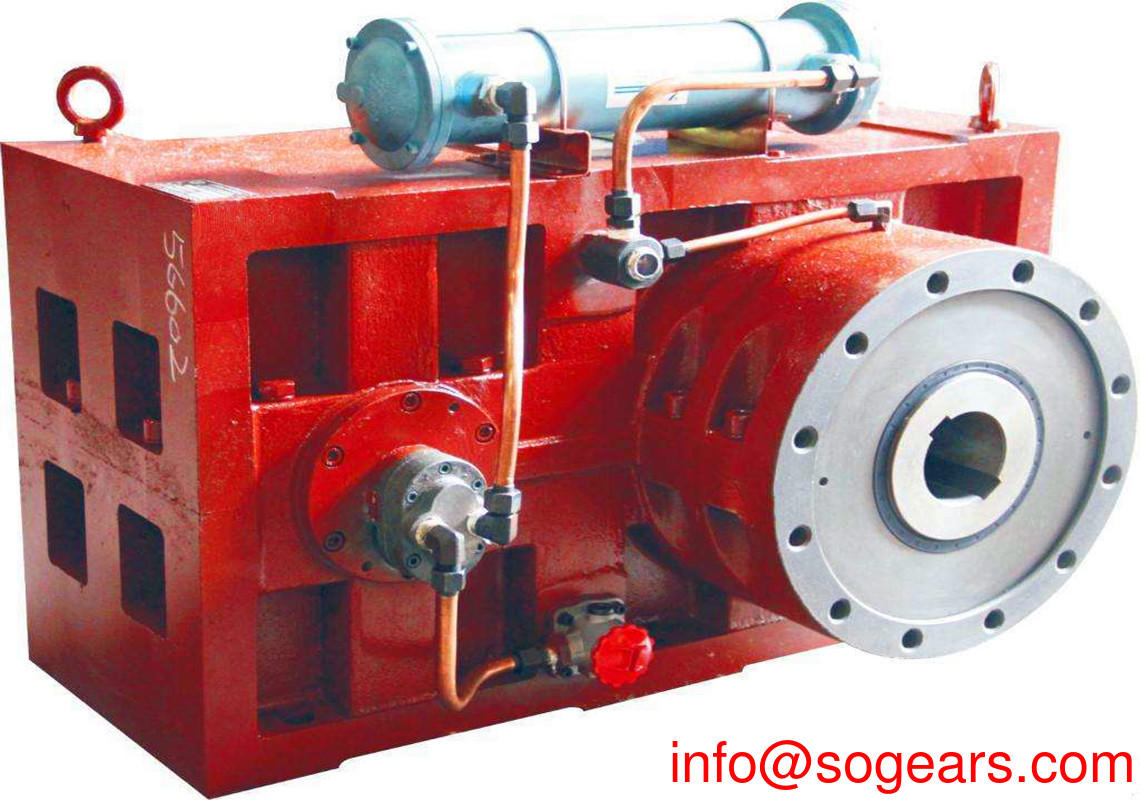

ZLYJ series nyuaj nto gearbox yog high-precision nyuaj-toothed siv tawv lub rooj xa xov tivthaiv tsim rau yas ntsia hlau extruder. Cov khoom lag luam tsim adopts cov kev qhia tshwj xeeb tau teev tseg hauv JB / T8853-2001. Nws muaj lub zog loj-alloy hlau rau iav thiab ua haujlwm thooj. Cov iav tau tiav los ntawm carburizing, quenching thiab sib tsoo. Iav raug yog GB10095-88.6. Hniav nto hardness HRC54-62. Kev tshaj tawm cov kabmob sab nraud muaj txheej txheem ntawm lub hauv paus kawg ntawm lub hollow tso zis tawm mus rau lub zog ua haujlwm axial quab yuam ntawm lub hau ntswj. Cov qauv txheem tseem ceeb xws li cov kabmob thiab cov ntsaws ruaj ruaj roj yog ua los ntawm cov khoom lag luam zoo hauv tsev, thiab tseem tuaj yeem nruab nrog cov khoom lag luam txawv teb raws li cov neeg siv khoom xav tau. Tag nrho lub tshuab muaj cov yam ntxwv ntawm lub ntim me, muaj peev xwm nqa tau, ruaj khov kis, lub suab qis thiab ua haujlwm siab. Cov khoom lag luam tau mus txog qib siab thoob ntiaj teb.

Cov yam ntxwv ua:

Kev sib xyaw ua ke ntawm lub npov thiab cov kabmob thawb tawm tsam cov khoom siv axial, thiab cov kabmob inferential tau teem rau ntawm cov roj ua haujlwm ntawm lub thawv roj av txhawm rau txhim kho kev ua haujlwm tau zoo.

Kev kho me me tuaj yeem siv los kho qhov chaw nruab nrab

Kev sib kis loj hauv lub zog, tuaj yeem tiv qhov siab lub zog thiab cov quab yuam

Lub Gearbox tshwj xeeb rau extruder yog kev sib kis uas muaj qhov siab hnyav muaj peev xwm tawv hniav nto nrog lub rooj zaum uas tsim los nrog siv cov khoom lag luam txawv teb chaws zoo sib xws rau cov ntsia hlau yas extruder. Cov khoom lag luam tsim adopts cov cuab yeej qhia kev ncaj qha los ntawm ZBJ19009-88. Nws cov yam ntxwv yog tias cov zog thiab cov tog hlau yog ua los ntawm lub zog loj lub zog hlau, kev ua los ntawm carburizing, quenching thiab kev sib tsoo. Iav qhov tseeb yog GB10095-88, qib 6. Hniav nto hardness HRC54 ~ 62. Ib qho loj-cov kabmob loj thawb txheej txheem tau teem rau sab pem hauv ntej kawg ntawm hollow input ncej yuav tiv taus cov axial thawb ntawm lub hau ntswj. Tag nrho lub tshuab muaj qhov zoo ntawm lub ntim me me, lub peev xwm nqa tau loj, kev sib kis ruaj khov, suab nrov thiab ua haujlwm siab.

Extruder tshwj xeeb Gearbox nta:

——Modular tsim, ntau qhov kis tau tus mob thiab qhov faib tawm zoo thiab tsim nyog;

——Qhov qauv qauv tsim kom haum rau txhua yam puag ncig teeb tsa kev teeb tsa;

—— Cov ntsuas qhov av yog qhov tseeb ntawm cov iav loj loj cov tshuab sib tsoo nrog cov kis tau zoo, lub suab qis thiab 98% ua haujlwm ntawm ntu;

Extrusion tshuab nplooj siab Gearbox siv tau cov mob:

1. Lub nrawm ntawm kev ua haujlwm siab ceev ntawm Gearbox tsis yog ntau dua 1500r / min.

2, qhov kub ua haujlwm ib puag ncig ua haujlwm yog 0-35C. Thaum qhov ntsuas kub ntau tshaj li cov kev cai, cov cuab yeej ua kom sov lossis cua txias tuaj yeem npaj cais nyias raws li tus neeg siv yuav tsum tau ua.

- Introduction

ZLYJ Yas extruder Gearbox yog ib hom qib high-precision nruj iav sib dhos tshwj xeeb tsim rau ib leeg ntsia hlau yas / roj hmab extruder. Noj JB / T 8853-2001 Cylindrical Yas extruder Gearbox raws li kev siv rau kev tsim, cov khoom lag luam siv lub siab-lub zog qis-carbon alloy steel rau lub zog thiab cov iav ncej, nrog cov hniav ya carbureted, quenched thiab hauv av, kom tau raws li lub iav precision ntawm Qib 6 (GB / T 10095) thiab hardness ntawm hniav dig HRC54 ~ 62. Muaj cov kabmob loj loj uas tau tsa ntawm sab xub ntiag ntawm cov zis tso zis los ua lub zog loj los ntawm cov ntsia hlau.

- Siv Daj

- Lub tswv yim kev sib hloov ntawm prime mover yuav tsum ≤ 1500 rpm.

- Lub peripheral ceev ntawm lub zog tsav yuav tsum ≤ 20m / s.

- Ua hauj lwm huab cua sov yuav tsum yog -40 ℃ ~ 45 ℃. Preheat lubricating roj rau saum toj no 0 ℃ los yog xaiv qhov kub roj kom tsis muaj roj thaum ntsuas qhov kub qis dua qis dua 0 ℃.

Nco ntsoov:

- Kev sib hloov yog muaj ob qho tib si forwards thiab rov qab. Txawm li cas los xij, lub khauj khaum siab ntawm qee hom Yas extruder Gearbox muaj ib txoj kev siv roj twj ncaj qha raws li qhov hloov kho rau cov zis tso tawm uas tig rau moos.

III. Yas extruder Gearbox Hom

Cov khoom lag luam npe: Thaum xa tawm, tag nrho cov yas extruder Gearbox tau txuas nrog cov npe los qhia kom meej hom, peev xwm, hnub ntau lawm, tus lej Hoobkas thiab lwm cov ntsiab lus rau kev saib xyuas, uas yuav tsum tsis tau muab tshem tawm thaum nkag mus.

- Txhim Kho thiab Txuas Txuas ntawm Yas extruder Gearbox

- Nco ntsoov tias qhov txhim kho lub hauv paus ntawm Yas extruder Gearbox yog qib, ruaj ntseg thiab ruaj khov. Ua tib zoo nteg tawm ntawm lub chaw teeb tsa hauv thaj chaw ua haujlwm tshwj xeeb. Thaum txhua lub thauj tog rau nkoj bolts raug khi kom nruj, xyuas kom meej cov ntsia hlau ntxig rau cov zis txuas tig tau ywj pheej thiab tsis tu ncua.

- Kev tiv thaiv kev them nyiaj yuam kev yuav tsum muaj hauv kev sib txuas ntawm Cov Kev Sib Txuas ntawm Yas Extruder Gearbox kom ua tus mover. Ua kom muaj kev kub siab ntawm kev sib txuas ntawm ib feem ntawm cov kab txuas ntawm axial Yas Extruder Gearbox lub thawb ncej. Txheeb xyuas qhov axial deviance thiab angular hloov chaw, qhov sib txawv ntawm ob qho no yuav tsum tsis pub dhau qhov txiaj ntsig kev tso cai ntawm kev sib txuas.

- Txheeb xyuas cov radial ntxiv durability ntawm tus ncej ntawm Yas extruder Gearbox raws li cov qauv khoom ntawm cov xwm txheej uas siv txoj hlua, lub log thiab cov log siv tau siv los tawm tswv yim thiab ua rau lub zog tsav ntawm Yas extruder Gearbox. Ntawm nruab nrab ib feem ntawm cov tswv yim nkag, lub zog tiv thaiv radial ntxiv yuav tsum tsis pub tshaj (N), nyob rau hauv uas lub sijhawm nkag ntawm Yas extruder Gearbox (NM).

- Tom qab kev teeb tsa, sau rau hauv Yas Extruder Gearbox lub tshuab roj kom txog thaum ncav cuag qhov chaw nruab nrab ntawm cov roj pointer thaum sib faib.

- Txuas mus rau thiab qhib ntawm lub taub dej txias kom kuaj xyuas seb cov pob qij ntshav puas los yog to.

- Qhib lub hwj chim ib ntus khiav Yas Extruder Gearbox yam tsis muaj teeb meem. Txheeb xyuas seb lub raj xa hluav taws xob puas los yog txia, qhov chaw thiab Cheebtsam daws thiab qhov nrov tshwm sim. Yas Extruder Gearbox tuaj yeem nqa yog tias txhua yam tsis tuaj yeem.

xim:

◇ Txiav tawm thiab tiv thaiv (los ntawm daim ntawv ceeb toom ntawm lub cim, thiab lwm yam) rov txuas lus txuas ntxiv ntawm lub hwj chim muab rau lub cev muaj zog ua ntej nruab nrog cov txuas.

◇ Tawm los ntawm rab rauj los yog lwm yam cuab yeej zoo sib xws tsis tso cai thaum kev sib tw cov couplings thiab cov cuab yeej me me mus rau tom qab kawg.

◇ Ua kom zoo siab qhov tseeb ntawm txoj siv tawv thaum txhim kho lub log tsheb.

◇ Tsis txhob nruab lossis tshem tawm cov ntsia hlau los ntawm kev sib zog ntawm kev tsim ntawm feem.

◇ Cov hood tiv thaiv yuav tsum muab rau sab nraud tig chaw ntawm Lub Yas Extruder Gearbox (xws li txuas, hlua khawm rub, thiab lwm yam).

◇ Tshem tawm kom huv lub antirust, av lossis lwm qhov stains ntawm qhov kawg thiab flange nto ntawm kev sib txuas. Cov kuab tshuaj tau tso cai rau kev ntxuav tab sis nws yuav tsum tiv thaiv kom tsis txhob ntws mus rau daim di ncauj foob ntawm cov khoom sib khi ntawm qhov kawg.

- Kev Ua Haujlwm ntawm Yas extruder Gearbox

Kev kuaj ua ntej ua haujlwm:

- Ua ntej kev ua haujlwm, xyuas seb Yas Extruder Gearbox puas muaj roj nplua rau qib tsim nyog hauv nws. Txhawb cov roj ntxiv yog tias tsis txaus.

- Txhua qhov chaw sib txuas yuav tsum nyab xeeb. Txhua yam khoom siv tiv thaiv yuav tsum ua tiav.

- Kuaj xyuas seb qhov chaw nyob ib puag ncig qis dua 0 ℃, yog tias muaj, preheat lub roj lubricating mus rau saum toj 0 ℃.

Kev ua haujlwm ntawm cov yas extruder Gearbox:

- Khiav lub Yas Extruder Gearbox rau 5 ~ 10 feeb yam tsis muaj thauj khoom (yog tias Yas Extruder Gearbox tau nruab nrog lub iav twj tso kua mis ntawm lub cev muaj zog, pib lub twj tso kua mis ua ntej) kom tsim nyog ntub cov bearings thiab zog. Yog tias Cov Yas Extruder Gearbox siv thawj zaug, tom qab kaw txoj haujlwm, ntxiv cov khoom siv thauj cov kauj ruam ntawm kauj ruam ntawm 20% ntawm cov ntaus nqi txhua lub sijhawm rau 1 ~ 2 teev kom txog thaum lub sijhawm thauj tag nrho. Muab kev pabcuam yog tias txhua yam tsis ua haujlwm.

- Thaum lub sijhawm ua haujlwm, saib xyuas thiab sau los ntawm lub sijhawm rau qhov ntsuas kub nce ntawm Lub Yas Extruder Gearbox. Yog tias qhov kub nce ntawm Cov Yas Extruder Gearbox ntau dua 70 ℃ lossis cov roj kub siab tshaj 100 ℃, nres lub Yas extruder Gearbox kom pom thiab daws cov teeb meem. Hu rau peb cov kev pab cuam tom qab muag yog tias tsim nyog. Hloov cov roj lubricating ua ntej pib siv yas Extruder Gearbox dua.

- Lub Yas Extruder Gearbox yuav tsum nres raws li hauv qab no: Kaw lub plhaw kev pub mis thiab, tom qab txhua cov ntaub ntawv hauv lub thoob tau raug thauj tawm, tua lub hwj chim mus rau Yas Extruder Gearbox (yog tias Yas Extruder Gearbox tau nruab nrog lub iav) lub twj tso kua mis ntawm lub cev muaj zog, kaw lub twj tso kua mis ua ntej)

- Khiav lub Yas Extruder Gearbox txhua txhua 2 rau 3 asthiv thaum qhov kev ncua ntev.

- Ua cov txheej txheem tiv thaiv xeb rau sab hauv thiab sab nraud Yas Extruder Gearbox thaum muaj kev ua haujlwm tsis pub dhau 6 lub hlis:

Sau rau hauv lubricating roj kom puv, tsho tiv thaiv ua haujlwm kawg thiab tsis muaj qhov saum npoo nrog cov ntaub ntawv los tiv thaiv xeb thiab tiv thaiv nrog lubricating roj tawm daim di ncauj ntawm kev sib khi qhov chaw ntawm axles tawm tsam kev nkag ntawm antirust.

xim:

Thaum lub sijhawm ua haujlwm thaum ntxov, lub tshuab tso kua roj yuav muaj lub suab nrov nrov uas yog los ntawm lub siab ntawm cov roj nplua thiab muaj qhov nqus loj los tiv thaiv cov roj twj, uas yuav maj mam tuag nrog rau qhov kub nce ntawm cov roj lubricating.

◇ Yog tias cov roj tso tawm cov suab nrov muaj lub suab nrov nrov thaum lub sijhawm kev ua haujlwm ntawm Yas extruder Gearbox, ntxuav lub taub lim roj kom tau txais cov roj hla.

◇ Saib xyuas qee lub sijhawm rau cov roj tawm ntawm Yas Extruder Gearbox thaum lub sijhawm ua haujlwm, thiab, yog tias muaj, tso tseg Yas Extruder Gearbox kom daws tau qhov teeb meem.

- Kho thiab Txij Nkawm

- Lub sijhawm sib nrug ntawm kev kho thiab kho txij nkawm

|

Lub sij hawm luv |

Kho thiab kho tawm |

|

Kev lag luam ib txwm |

Txheeb xyuas qhov ntsuas kub ntawm Yas tshuab riam Gearbox: tsis pub ntau tshaj 90 ℃ thaum siv cov ntxhia roj lubricating roj tsis pub ntau tshaj 100 ℃ thaum siv cov roj ua kom zoo nkauj Txheeb xyuas seb puas muaj suab txawv txav ntawm Yas extruder Gearbox Txheeb xyuas seb puas muaj dej ntawm Cov Yas Extruder Gearbox |

|

Tom qab 500 ~ 800 teev sijhawm ua haujlwm |

Ua ntej lubricating roj hloov tom qab pib ua haujlwm Xyuas cov roj qib txhawm rau txhawm rau txiav txim siab roj txhaws |

|

Txhua txhua 3000-teev sijhawm ua haujlwm, tsawg kawg ib zaug ib nrab xyoo |

Txheeb xyuas cov roj lubricating, thiab, nyob rau hauv qhov chaw sab nraum zoov lossis ntub ib puag ncig, xyuas kom meej tias cov ntsiab lus dej hauv lubricating roj yuav tsum tsis tshaj 500ppm Hloov cov ntxhia lubricating roj (ua hauj lwm teev tsawg dua 8h ib hnub) Ntxuav cov pa roj huv |

|

Xws li kho mob ib zaug, tsawg kawg ib zaug 3 hlis |

Hloov cov ntxhia lubricating roj (ntev lub sijhawm ua haujlwm tas li) Txheeb xyuas seb puas muaj qhov sib koom sib tsoo Txheeb xyuas cov xwm txheej tsis huv thiab lubricating thiab txias Ntxuav lub lim ntawm lubricating roj thiab hloov lim lim yog tias yuav tsum tau |

|

Raws li kev ua haujlwm ib zaug, tsawg kawg ib xyoos ib zaug |

Hloov cov hluavtaws ua kom zoo nkauj |

|

Xws li ib puag ncig thiab kev ua haujlwm raug mob |

Txhim kho lossis hloov kho cov tshuaj pleev xim (xeb) rau saum npoo Ntxuav cov sab nrauv thiab ntawm Yas Extruder Gearbox Xyuas cov khoom siv ntxiv txuas nrog |

- Lub sijhawm sib nrug ntawm lubricating roj hloov

Tsis tu ncua hloov cov roj lubricating ntawm hom tshwj xeeb Yas extruder Gearbox uas ua haujlwm nyob rau hauv ib puag ncig hnyav. Daim duab hauv qab no qhia lub sijhawm sib nrug ntawm lubricating roj hloov nyob rau hauv ib puag ncig ib puag ncig. CLP HC yog hais txog PAO hluavtaws lubricating roj.

(1) Lub sijhawm ua haujlwm (2) Nruam ntsuas kub hauv roj da dej (qhov nruab nrab ntawm 70 ℃)

VII. Txhaum kev soj ntsuam thiab cov kev daws teeb meem

|

Faults |

Ua rau |

Solutions |

|

Faults |

Ua rau |

Solutions |

|

Suab nrov tsis zoo thiab tsis tu ncua |

A. Rolling / milling suab nrov: kev coj tus kheej ua kom puas B. Rho suab nrov: tsis zoo joggling |

A. Tshawb cov roj lubricating thiab hloov cov kabmob B. Hu rau Guomao |

Xau ntawm lubricating roj: hlws nto ntawm Yas extruder Gearbox Xaus npoo npoo ntawm Yas extruder Gearbox Npog ntawm pom qhov ntawm Yas extruder Gearbox Sealing kis ntawm tsav ncej Roj paug ntsaws Cua ntsaws |

Txo ntawm txuas cov seem ntawm Yas extruder Gearbox Loosening ntawm kev txuas fastener Kev teeb tsa tsis raug ntawm qhov chaw sib khi Kev puas tsuaj / puas ntawm kev sib khi ntawm qhov chaw Xoob kev twb kev txuas Ntau dhau cov roj theem ntawm lubricating roj Tsis yog installation |

Kos rau qhov txuas txuas thiab muab khi kom ruaj yog qhov xoob xoob yog tias xav tau Kos rau qhov ntim sib khi thiab hloov nws yog tias xav tau Tshawb xyuas cov roj theem / txhim kho txhawm Hu rau Guoma |

|

|

Suab nrov tsis zoo thiab tsis nquag |

Tsis zoo ntawm lubricating roj |

Tshawb cov roj nplua nyeem, nres lag luam thiab tiv tauj Guomao |

||||

|

Lub suab tsis zoo nyob rau hauv cov chaw seem ntawm Yas Extruder Gearbox |

Cov Ntsuas Cov Yas Extruder Gearbox looses |

Txheeb cov fasteners thiab siv cov uas tau teev tseg |

||||

|

Lub siab kub dhau ntawm kev ua haujlwm |

A. Kom ntau cov roj lubricating B. Kev laus thiab kev tsis zoo ntawm lubricating roj C. Kev npliag siab tsis zoo nyob rau hauv lubricating roj D. Kev puas tsuaj ntawm lub twj tso kua mis E. Txhaum ntawm lub zog cua txias |

A. Tshawb xyuas cov roj theem thiab hloov kho yog tias xav tau B. Txheeb xyuas lub sijhawm hloov cov roj lubricating C. Tshawb cov roj nplua nyeem D. Tshawb cov twj tso kua roj thiab hloov nws E. Kuaj cov cua txias |

Siab kub dhau ntawm cov kabmob |

A. Tsis txaus ntseeg lubricating roj B. Kev laus thiab kev tsis zoo ntawm lubricating roj C. Kev puas tsuaj ntawm lub tshuab nqus dej D. Kev puas tsuaj ntawm kev coj tus kheej |

A. Tshawb xyuas cov roj theem thiab hloov kho yog tias xav tau B. Txheeb xyuas lub sijhawm hloov cov roj lubricating C. Kos lub tshuab nqus dej twj tso kua mis thiab hloov nws D Kuaj cov kabmob thiab hloov nws |

|

|

Tshaj-kub txog ntawm qhov sib khi taw tes ntawm qhov xaus hauv kev ua haujlwm |

Kev tu tsis txaus ntawm kev txuas ntawm tus ncej thaum lub sijhawm teeb tsa Khiav-hauv kev sib khi ntawm qhov chaw thiab ntug kawg |

Huv huv pluaj kawg Suav muab saib li qub Hu rau Guoma |

Thaum hu rau Guomao, thov muab cov ncauj lus nram qab no:

|

Ua kom tiav cov ntaub ntawv ntawm nameplate |

- |

Hom thiab qhov kawg ntawm kev yuam |

- |

Lub sij hawm thiab qhov tshwm sim ntawm kev yuam kev tshwm sim |

- |

Ua rau |

VIII. Xaiv Cov Roj Roj

Lub viscosity ntawm lubricating roj yuav tsum txiav txim siab raws li kev siv ntu nrawm V, ib puag ncig ua haujlwm lossis hom kev ua haujlwm ntawm lub zog ceev:

Thaum V≤2.5m / s lossis qhov ntsuas kub ib puag ncig yog nyob rau hauv 35 ℃ ~ 50 ℃, xaiv CKC320 nruab nrab-ntim cov khoom lag luam kaw qhov roj lossis CKD320 hnyav-thauj cov khoom lag luam raug kaw;

Thaum V > 2.5m / s lossis yuam kom circulating lubrication raug thov, xaiv CKC220 nruab nrab-ntim kev lag luam kaw qhov roj tsheb lossis CKD220 hnyav-thauj cov khoom siv roj kaw.

Roj nplua nyeem

Lubricating roj tsis pom zoo rau yas extruder Gearbox. Tiv tauj peb yog tias xav tau.

Saib Ntxiv HauvLubricating Roj Sib Piv Cov Lus rau cov roj hauv tsev thiab txawv teb chaws lubricating khoom

- Hnav Qhov

Cov npe ntawm Cov Khoom Sib Tw ntawm Yas extruder Gearbox

Cov Ntawv Sau Ntawm Yas extruder Gearbox

Annex - Lubricating Roj Sib Piv Cov Lus (Ntxhia Lubricating Roj):

|

Qeb |

ISO TSO |

AGMA |

Tsom |

Hom Lubricating Roj |

Viscosity / 40 ℃ |

Khov Taw ℃ |

|

Qeb |

ISO TSO |

AGMA |

Tsom |

Hom Lubricating Roj |

Viscosity / 40 ℃ |

Khov Taw ℃ |

|

220 |

220 |

5EP |

Hlis ntuj nqeg |

Qib BG 220 |

220 |

-21 |

320 |

320 |

6EP |

Hlis ntuj nqeg |

Qib BG 320 |

320 |

-18 |

|

|

BP |

Energol GR-XP220 |

210 |

-27 |

BP |

Energol GR-XP320 |

305 |

-24 |

|||||||

|

Castrol |

Alpha SP220 |

220 |

-21 |

Castrol |

Alpha SP320 |

320 |

-21 |

|||||||

|

Castrol |

Alphamax 220 |

220 |

-24 |

Castrol |

Alphamax 320 |

320 |

-18 |

|||||||

|

Chevron |

Muaj Roj EP220 |

220 |

-12 |

Chevron |

Muaj Roj EP320 |

320 |

-9 |

|||||||

|

vajtswv poj niam |

Liaj CLP220 |

220 |

-18 |

vajtswv poj niam |

Liaj CLP320 |

320 |

-18 |

|||||||

|

Esso |

Txij Nkawm Teev Kua Muag EP220 |

226 |

-30 |

Esso |

Txij Nkawm Teev Kua Muag EP320 |

332 |

-27 |

|||||||

|

Exxon |

Txij Nkawm Teev Kua Muag EP220 |

226 |

-30 |

Exxon |

Txij Nkawm Teev Kua Muag EP320 |

332 |

-27 |

|||||||

|

Fuchs |

Renolin CLP220 Ntxiv |

223 |

-23 |

Fuchs |

Renolin CLP320 Ntxiv |

323 |

-21 |

|||||||

|

Ntug dej hiav txwv |

Gulf Tshooj Roj Ntsha HD220 |

219 |

-19 |

Ntug dej hiav txwv |

Gulf Tshooj Roj Ntsha HD320 |

300 |

-12 |

|||||||

|

Klüber |

Klüberoil GEM 1-220 |

220 |

-15 |

Klüber |

Klüberoil GEM 1-320 |

320 |

-15 |

|||||||

|

Kuwait |

Q8 Nia 220 |

220 |

-21 |

Kuwait |

Q8 Nia 320 |

320 |

-18 |

|||||||

|

mobile |

Mobilgear 630 |

207 |

-18 |

mobile |

Mobilgear 632 |

304 |

-18 |

|||||||

|

mobile |

Mobilgear XMP 220 |

220 |

-24 |

mobile |

Mobilgear XMP 320 |

320 |

-18 |

|||||||

|

Molub-Alloy |

MA-90/220 |

220 |

-18 |

Molub-Alloy |

MA-90/320 |

320 |

-15 |

|||||||

|

Optimol |

Optigear BM 220 Nws |

233 |

-15 |

Optimol |

Optigear BM 320 Nws |

338 |

-15 |

|||||||

|

Petro Canada |

Lub Hnub Qub EP220 |

223 |

-30 |

Petro Canada |

Lub Hnub Qub EP320 |

320 |

-21 |

|||||||

|

Plhaub |

Omala Roj F220 |

220 |

-21 |

Plhaub |

Omala Roj F320 |

320 |

-18 |

|||||||

|

Texaco |

Tshooj 220 |

209 |

-21 |

Texaco |

Tshooj 320 |

304 |

-18 |

|||||||

|

Tag nrho cov |

Carter EP220 yog |

220 |

-12 |

Tag nrho cov |

Carter EP320 yog |

320 |

-12 |

|||||||

|

Tribol |

Pab Pawg 1100/220 |

222 |

-25 |

Tribol |

Pab Pawg 1100/320 |

317 |

-23 |

|||||||

|

GB5903-95 |

domestic |

TIAB SA 220 |

198 ~ 242 |

≤-8 |

GB5903-95 |

domestic |

TIAB SA 320 |

288 ~ 352 |

≤-8 |

|||||

|

GB5903-95 |

domestic |

QAB 220 |

198 ~ 242 |

≤-8 |

GB5903-95 |

domestic |

QAB 320 |

288 ~ 352 |

≤-8 |

|||||

Annex - Lubricating Roj Sib Piv Cov Lus (POV Cov Khoom Hluav Taws Xob Lubricating Roj):

|

Qeb |

ISO TSO |

AGMA |

Tsom |

Hom Lubricating Roj |

Viscosity cSt Cov |

Khov Taw ℃ |

|

Qeb |

ISO TSO |

AGMA |

Tsom |

Hom Lubricating Roj |

Viscosity cSt Cov |

Khov Taw ℃ |

||

|

40 ℃ |

100 ℃ |

40 ℃ |

100 ℃ |

|||||||||||||

|

220 |

220 |

5EP |

vajtswv poj niam |

Hauv HCLP220 |

220 |

25.1 |

-36 |

320 |

320 |

6EP |

vajtswv poj niam |

Hauv HCLP320 |

320 |

33.9 |

-33 |

|

|

Esso |

Txij Nkawm Teev Kua Muag EP220 |

232 |

26.5 |

-39 |

Esso |

Txij Nkawm Teev Kua Muag EP320 |

328 |

34.3 |

-36 |

|||||||

|

Exxon |

Txij Nkawm Teev Kua Muag EP220 |

232 |

26.5 |

-39 |

Exxon |

Txij Nkawm Teev Kua Muag EP320 |

328 |

34.3 |

-36 |

|||||||

|

Fuchs |

Renolin Unisyn CLP220 Cov |

221 |

25.8 |

-42 |

Fuchs |

Renolin Unisyn CLP320 Cov |

315 |

33.3 |

-39 |

|||||||

|

Klüber |

Klübesynth EG 4-220 |

220 |

26 |

-40 |

Klüber |

Klübesynth EG 4-320 |

320 |

38 |

-40 |

|||||||

|

mobile |

Mobilgear SHC XMP 220 |

220 |

28.3 |

-45 |

mobile |

Mobilgear SHC XMP 320 |

320 |

37.4 |

-39 |

|||||||

|

mobile |

Mobilgear SHC 220 |

213 |

26 |

-51 |

mobile |

Mobilgear SHC 320 |

295 |

34 |

-48 |

|||||||

|

Optimol |

Optigear Synthic A220 |

210 |

23.5 |

-36 |

Optimol |

Optigear Synthic A320 |

290 |

30 |

-36 |

|||||||

|

Plhaub |

Omala Roj HD220 |

220 |

25.5 |

-48 |

Plhaub |

Omala Roj HD320 |

320 |

33.1 |

-42 |

|||||||

|

Texaco |

Tus Ntxim Hlub EP220 |

220 |

25.8 |

-48 |

Texaco |

Tus Ntxim Hlub EP320 |

320 |

35.2 |

-39 |

|||||||

|

Tag nrho cov |

Carter EP / HT220 |

220 |

25 |

-39 |

Tag nrho cov |

Carter EP / HT320 |

320 |

33 |

-36 |

|||||||

|

Tribol |

Pab Pawg 1510/220 |

220 |

24.6 |

-42 |

Tribol |

Pab Pawg 1510/320 |

330 |

33.2 |

-39 |

|||||||

|

Tribol |

Pab Pawg 1710/220 |

220 |

- |

-33 |

Tribol |

Pab Pawg 1710/320 |

320 |

- |

-30 |

|||||||

|

domestic |

Great phab ntsa |

4405/220 |

221.3 |

- |

-42 |

|

|

|

|

|

|

|||||

|

domestic |

Great phab ntsa |

4406/220 |

225.3 |

- |

-42 |

domestic |

Great phab ntsa |

4406/320 |

330.5 |

- |

-40 |

|||||

Tib lub hau ntswj extruder tso

Tib qho ntsia hlau feem ntau muab faib ua peb ntu hauv qhov ntev ntev. Qhov ua tau ntev ntawm peb ntu yog txiav txim siab raws li lub cheeb ntawm lub hau ntswj thiab lub suab ntawm cov ntsia hlau. Feem ntau, nws muab faib ua ib feem peb.

Cov xov kawg ntawm qhov chaw nres nkoj cov khoom hu ua ntu ntu: cov khoom yuav tsum tau ntim ntawm no, tab sis nws yuav tsum preheated thiab compacted. Yav dhau los, tus qub extrusion txoj kev ntseeg ntseeg tias cov khoom siv ntawm no yog xoob, thiab tom qab ntawd ua pov thawj tias cov khoom ntawm no yog qhov tseeb cov ntsaws, uas yog hais, cov khoom ntawm no yog cov khoom zoo li ntsaws tom qab raug nyem, yog li nws yog nws txoj haujlwm ntev npaum li qhov kev ua haujlwm conveying tiav.

Ntu ob hu ua seem ntu. Nyob rau lub sijhawm no, qhov ntim ntawm qhov zawj yog maj mam txo los ntawm qhov loj mus rau loj, thiab qhov kub kom ncav cuag lub degree ntawm kev ua kom tiav ntawm cov khoom. Ntawm no, qhov nias tau tsim los ntawm cov ntu ntu peb, qhov uas nws tau compressed rau ib qho, uas yog hu ua kev sib piv ntawm cov ntsia hlau - 3: 1, qee cov tshuab kuj tau hloov pauv, thiab cov khoom tiav cov khoom tiav hauv peb theem.

Ntu peb yog ntu metering, qhov twg cov khoom tswj qhov kub kub rau yas, tsuas yog muaj tseeb thiab muaj ntau qhov thauj cov khoom yaj raws li lub tshuab hluav taws xob metering los muab lub taub hau, thaum lub sijhawm kub tsis tuaj yeem qis dua qhov ntsuas kub ntawm cov khoom hluav taws xob, feem ntau me ntsis Cov.

Extruder zog txuag kho editor

Lub zog txuag ntawm lub tshuab txuas ntxiv tau muab faib ua ob ntu: ib qho yog lub zog thiab lwm qhov yog qhov khoom cua sov.

Lub zog txuag: feem ntau ntawm cov inverters siv. Txoj kev txuag hluav taws xob yog kev txuag lub zog ntawm lub cev muaj zog. Piv txwv li, lub zog tiag tiag ntawm lub cev muaj zog yog 50Hz, thiab koj tsuas xav tau 30Hz nyob rau hauv ntau lawm los tsim kom txaus. Kev siv zog ntau dhau tsis muaj txiaj ntsig. Khib nyiab, lub inverter yog los hloov cov hluav taws xob tso zis tawm ntawm lub cev muaj zog kom ua tiav lub zog txuag.

Lub zog txuag nyob rau hauv cua sov ib feem: feem ntau ntawm lub zog txuag hauv cua sov yog lub zog txuag los ntawm lub tshuab hluav taws xob, thiab lub zog txuag hluav taws xob yog li 30% ~ 70% ntawm lub qub resistor nplhaib.

cov txheej txheem ua haujlwm

Cov khoom siv yas nkag mus rau lub tshuab extruder los ntawm lub plhaw, thiab thauj mus rau tom ntej los ntawm kev sib hloov ntawm cov ntsia hlau. Thaum nyob hauv kev txav mus tom ntej, cov khoom siv tau rhaub los ntawm qhov chim, sheared los ntawm lub hau ntswj thiab compressed kom yaj cov khoom. Yog li, qhov kev hloov ntawm peb lub xeev ntawm lub xeev glassy, lub xeev elastic siab, thiab lub xeev khov dej tau tiav.

Thaum hais txog ntawm cov pa tawm, cov khoom hauv cov dej ntws hauv lub xeev tau dhau los ntawm kev tuag muaj ib hom duab, thiab tom qab ntawd dhau los ua kev txuas ntxiv uas muaj ntu ntu thiab qhov ncauj zoo li tus neeg tuag. Tom qab ntawd nws txias thiab zoo li tsim lub iav rau hauv lub xeev, yog li muab cov ntu los ua.

Cov kws sau phau ntawv

Hauv lub tshuab txuas ntxiv, feem ntau, qhov yooj yim thiab ntau yam yog ib qho ntsia hlau extruder. Nws feem ntau suav nrog: XNUMX seem: kis, pub khoom noj, lub thoob, ntsia hlau, tshuab lub taub hau thiab tuag.

Ntu ntu

Cov kis kab sib kis feem ntau yog tsim nrog lub tshuab hluav taws xob, lub thawv txo thiab lub pob bearings. Thaum lub sijhawm txheej txheem kev rho tawm, cov ntsia hlau ceev yuav tsum ruaj khov thiab tsis tuaj yeem hloov nrog qhov hloov pauv ntawm lub ntswj ntsia hlau, kom tswj tau qhov zoo tsis sib thooj ntawm cov khoom tau txais. Txawm li cas los xij, nyob rau ntau lub sijhawm sib txawv, cov ntsia hlau tuaj yeem raug hloov pauv kom ua tiav qhov kev ua tiav uas ib lub cuab yeej tuaj yeem tshem tawm cov plastics lossis cov khoom sib txawv. Yog li no, feem ntau siv AC commutator lub cev muaj zog, DC lub cev muaj zog thiab lwm yam khoom kom ua tiav qhov hloov ntawm qhov tsis hloov mus rau qhov siab, qhov dav dav ntsia hlau ceev yog 10 ~ 100 rev / min.

Kev ua haujlwm ntawm lub tshuab xa hluav taws xob yog tsav cov ntsia hlau, uas cov khoom siv txhawb lub zog thiab nrawm uas yuav tsum muaj los ntawm lub ntsia hlau thaum lub txheej txheem txheej txheem, feem ntau muaj lub cev muaj zog, lub Gearbox thiab cov kabmob. Raws li qhov pom tias cov qauv cia li zoo ib yam, cov nqi tsim tawm ntawm Gearbox yog ntxaib sib luag rau nws sab nraud qhov ntev thiab qhov hnyav. Vim tias cov duab thiab qhov hnyav ntawm Gearbox yog qhov loj, nws txhais tau tias muaj ntau cov ntaub ntawv noj thaum lub sijhawm tsim khoom, thiab cov kabmob siv kuj tseem loj, uas ua rau tsim nqi tsim khoom.

Cov khoom siv pub mis

Feem ntau ntawm cov khoom noj khoom haus yog pelletized, tab sis cov strips lossis hmoov txhuam kuj tseem siv tau. Cov khoom siv thauj khoom feem ntau siv lub conical hopper nrog qhov ntim yuav tsum tsawg kawg ib teev. Ib lub tshuab kaw tau muab rau hauv qab ntawm lub plhaw mus kho thiab txiav qhov khiav, thiab pom lub qhov taub thiab lub tshuab ntsuas tau muab tso rau ntawm sab plhaw. Qee qhov kev cia siab kuj tseem yuav muaj lub siab nyem pab lossis cua kub uas tiv thaiv cov tsiaj txhu kom tsis txhob nqus noo los ntawm huab cua, lossis qee lub cartridges kuj tseem muaj lawv tus kheej agitator rau kev pub mis lossis pub mis.

Hopper

Lub plhaw feem ntau yog tsim nyob rau hauv hom qauv. Lub qhov rais qhib ntawm ib sab ntawm lub plhaw cia kom pom cov khoom qib thiab cov khoom noj. Hauv qab ntawm lub plhaw muaj qhov qhib thiab kaw qhov rooj kom nres thiab kho tus nqi noj. Npog rau sab saum toj ntawm lub plhaw mus txhawm rau txhawm rau tiv thaiv plua plav, ya raws thiab tsis huv ntawm kev poob rau hauv. Thaum xaiv cov khoom ntawm lub plhaw, nws yog qhov zoo tshaj plaws rau kev siv lub teeb yuag, corrosion-resistant thiab yooj yim tshuab, feem ntau siv txhuas thiab stainless hlau daim hlau. Qhov ntim ntawm lub plhaw yog nyob ntawm qhov loj ntawm qhov txuas ntxiv thiab txoj kev thauj khoom. Feem ntau, kev rho tawm cov nyiaj ntawm extruder yog los ntawm 1 mus rau 1.5 teev.

Muaj ob txoj hauv kev pub mis: phau ntawv pub mis thiab kev pub mis tsis siv neeg. Tsis siv neeg pub mis feem ntau suav nrog kev pub mis rau lub caij nplooj hlav, tawg pub mis, nqus plua plav pub mis, kev siv khoom conveying thiab lwm yam. Nyob rau hauv dav dav, me me extruders yog manually thauj khoom thiab cov extruders loj loj tau sau cia.

Kev faib tawm ntawm txoj kev pub mis

1 Lub ntiajteb txawj nqus noj:

Lub hauv paus ntsiab lus - Cov khoom siv nkag mus rau hauv pob los ntawm nws tus kheej qhov hnyav, suav nrog kev pub zaub mov noj, pub mis rau lub caij nplooj ntoo hlav, thiab tua.

Nta - cov qauv yooj yim thiab tus nqi qis. Txawm li cas los xij, nws yog ib qho yooj yim ua rau kev pub mis tsis sib xws, uas cuam tshuam rau qhov zoo ntawm qhov chaw. Nws tsuas yog tsim rau qhov loj me me extruders.

2 Yuam kev pub mis:

Lub hauv paus ntsiab lus - Nruab ib qho khoom siv rau hauv lub plhaw uas siv rau sab nraud mus rau cov khoom siv, yuam cov khoom rau hauv qhov chim ntawm qhov txuas.

Cov Nta - tuaj yeem kov yeej qhov "choj" tshwm sim, kom cov khoom noj khoom haus txawm. Cov pub ntsia hlau tau tsav los ntawm lub hau ntswj extruder los ntawm kev siv lub tshuab tsav los kho nws txoj kev nrawm rau cov ntsia hlau ua kom nrawm. Tshaj cov khoom siv tiv thaiv muaj peev xwm ua kom thaum lub chaw nres nkoj pub thaiv, yog li zam kom tsis txhob muaj kev puas tsuaj rau cov khoom siv pub mis.

Cartridge

Feem ntau, nws yog cov khoom siv hlau ua cov kav hlau ua los ntawm cov hlau tsis sib txuas lossis cov yeeb yaj kiab sib xyaw ua ke nrog cov hlau tsis xeb hlau. Nws cov yam ntxwv yooj yim yog qhov kub thiab siab tsis kam, hnav zoo thiab corrosion tsis kam. Feem ntau, qhov ntev ntawm lub thoob yog 15 txog 30 npaug ntawm nws txoj kab uas hla, thiab qhov ntev yog xws li tias cov khoom muaj txaus txaus thiab plasticized uniformly. Lub thoob yuav tsum muaj tuab thiab tuab. Sab hauv yuav tsum du, tab sis qee qhov ntawm cov kas tham tau txua nrog ntau cov duab puab kom muaj kev sib txhuam nrog cov yas. Cov tshuab ua hluav taws xob, cov khoom siv tswj kub thiab lub tshuab cua txias tau muab rau sab nraud ntawm cov thoob nrog cov roj uas tsis kam, cov inductors thiab lwm txoj kev ua kom sov.

Muaj peb daim ntawv ntawm cov khoom hauv lub thoob:

(1) ib txoj siv thoob

Txoj kev ua - ua tiav ntawm tag nrho cov khoom siv.

Cov txiaj ntsig tau yooj yim - yooj yim los xyuas kom meej cov khoom lag luam tsim tau thiab qhov tseeb ntawm lub rooj sib txoos, tuaj yeem ua haujlwm yooj yim rau lub rooj sib txoos ua haujlwm, lub tog raj kheej rhuab tusyees, thiab ntau daim ntawv thov.

Kev tsis zoo - Vim tias qhov loj qhov loj qhov ntev thiab qhov ua kom ua haujlwm siab, cov tseev kom muaj rau kev ua khoom siv kuj tseem nruj heev. Lub ntsej muag sab hauv sab hauv qhov chim yog qhov nyuaj kho tom qab hnav.

(2) Cov khoom sib xyaw

Kev ua txheej txheem - lub thoob yog ua tiav nyob rau ntau theem, thiab tom qab ntawd cov ntu tau txuas los ntawm flanges lossis lwm daim ntawv.

Cov txiaj ntsig - kev ua haujlwm yooj yim, hloov tau yooj yim rau kev hloov pauv ntawm cov tog, feem ntau yog siv los hloov cov duab ntawm cov ntsia hlau.

Qhov tsis zoo - kev ua tiav siab qhov yuav tsum tau ua, vim muaj ntau ntu, nws yog qhov nyuaj ua kom paub meej cov coaxiality ntawm txhua ntu, qhov txuas flange tawg qhov tsis sib xws ntawm cov cua sov cov cua sov, nce siab poob, cua sov thiab txias zog cov chaw teeb tsa thiab txij nkawm nyuaj dua

(3) Bimetallic thoob

Cov txheej txheem txheej txheem - Inlay lossis nrum txheej ntawm cov khoom siv ntawm cov hlau tsis muaj steel sab hauv cov pa roj carbon zoo tib yam lossis cov hlau nrum. Nws tsis tsuas yog ua tau raws li cov khoom xav tau ntawm lub thoob ntim, tab sis tseem txuag cov khoom siv hlau.

1 Bushing cartridge: Daim cartridge tau txig nrog cov hloov ua ke ntawm cov hlau bushing. Txuag cov khoom muaj nqis, cov bushings tuaj yeem hloov, thiab lub neej kev ua haujlwm yog nce ntxiv. Tab sis nws cov qauv, kev tsim khoom thiab kev sib dhos yog qhov nyuaj ntxiv.

2 Casting lub thoob: Ib txheej txheej ntawm kwv yees li 2 hli tuab alloy yog centrifugally cam khwb cia rau sab hauv phab ntsa ntawm lub thoob, thiab tom qab ntawd qhov xav tau sab hauv lub cheeb ntawm cov thoob yog tau los ntawm kev sib tsoo. Cov txheej txheej txheej alloy yog zoo sib txuas rau lub hauv paus ntawm lub thoob, thiab cov lus sib khi raws txoj kab xev qhov ntev yog qhov sib luag, tsis muaj qhov sib luag rau tev tawm, tsis tawg, muaj kev ua haujlwm zoo dua, thiab muaj siab hnav tsis kam. lub neej ntev.

1) Qhov ntev ntawm txoj kab npoo ntawm sab hauv phab ntsa ntawm txoj kab pub khoom noj yog qhib

Txhawm rau nce cov khib nyiab thauj tus nqi, ib txoj kev yog kom nce cov coefficient ntawm kev sib txhuam ntawm saum npoo ntawm lub tog raj kheej los ntawm cov khoom thauj kev tshawb xav. Lwm txoj kev yog los nce thaj tsam ntawm cov khoom ntawm qhov chaw nres nkoj pub los ntawm qhov chaw hla ntu sib tshuam rau lub ntsia hlau axis. Qhov tsim ntawm qhov ntev ntawm qhov zawj nyob rau sab hauv phab ntsa ntawm lub thoob pub khoom noj thiab qhov txuas ntawm cov phab ntsa sab hauv ntawm ntu ntu ntawm cov khoom noj ze rau ntawm qhov chaw pub khoom noj yog qhov tshwj xeeb ntawm ob txoj kev.

2) Yuam kom txias txias khoom noj seem ua laj kab

Kuj tseem muaj txoj hauv kev los nce nqi ntawm cov khib nyiab thauj. Nws yog kom txias qhov chaw pub mis noj cov khoom noj, lub hom phiaj yog ua kom qhov kub ntawm cov khoom yuav tsum tau ua qis dua qhov taw tes los yog qhov chaw yaj, kom tsis txhob muaj qhov pom ntawm yaj yaj kom tswj tau cov khoom khov ntawm cov khoom siv.

Nrog rau cov qauv saum toj no, kev ua haujlwm conveying tau nce los ntawm 0.3 mus rau 0.6, thiab tus nqi ntawm qhov kev rho tawm tsis raug rhiab rau kev hloov pauv hauv lub taub hau siab.

Cov ntsia hlau yog qhov txuas ntawm lub extruder thiab yog qhov tseem ceeb ntawm cov txuas tawm. Kev ua tiav ntawm cov ntsia hlau txiav txim siab cov khoom tsim, yas zoo, kev faib tawm ntawm cov muab tub lim, yaj kub, siv fais fab, thiab lwm yam ntawm cov extruder. Cov. Nws yog qhov tseem ceeb tshaj ntawm lub tshuab txuas ntxiv, uas tuaj yeem cuam tshuam ncaj rau daim ntawv thov ntau yam thiab kev tsim khoom ntawm cov extruder. Kev sib hloov ntawm cov ntsia hlau tawm sab nrawm dhau qhov siab tshaj tawm ntawm cov yas. Cov yas tuaj yeem txav, nias thiab tau txais qee qhov kub ntawm qhov kev sib txhuam hauv lub tog raj kheej. Cov yas sib xyaw ua ke thiab cov yas ntau thaum lub zog txav ntawm lub tog raj kheej, thiab khov dej ntws ntws tawm lub xeev yaj tau tsim thaum tab tom ua extruded kom ntws los ntawm qhov tuag kom tau txais cov duab uas xav tau. Zoo li lub thoob, cov ntsia hlau kuj tau ua los ntawm lub zog siab, kub thiab corrosion resistant alloy.

Vim ntau yam ntawm cov yas, lawv cov khoom kuj tseem muaj qhov sib txawv. Yog li ntawd, hauv kev ua haujlwm tiag tiag, txhawm rau hloov kho rau cov kev xav tau sib txawv ntawm cov yas, cov hom screws uas yuav tsum tau muaj qhov sib txawv, thiab cov qauv kuj tseem muaj qhov sib txawv. Txhawm rau kom ua tiav qhov ua tau zoo ntawm cov plastics kom ua tiav kev thauj mus los, kev tshem tawm, kev sib xyaw thiab yas.

Cov duab pom ob peb tus screws ntau dua. Cov kev txiav txim siab tseem ceeb qhia cov yam ntxwv ntawm cov ntsia hlau muaj xws li cov nram qab no: taub, lub ntsej muag sib piv, seem piv, lub suab, qhov zawj qhov tob, lub kaum sab xis Helix, ntsia hlau thiab lub qhov cub, thiab lwm yam. Feem ntau cov ntsia hlau loj tshaj D yog kwv yees li 45 txog 150 hli. Raws li lub hau ntswj ntsia hlau loj ntxiv, kev ua haujlwm ntawm lub tshuab txuas ntxiv nce raws, thiab cov khoom lag luam ntawm cov extruder yog sib npaug mus rau cov square ntawm cov ntsia hlau diam D. Qhov sib piv ntawm qhov ntev ntev rau txoj kab uas ua haujlwm ntawm cov ntsia hlau (xa mus rau raws li cov nam piv, qhia raws li L / D) feem ntau yog 18 ~ 25. Loj L / D tuaj yeem txhim kho cov khoom kub hloov khoom, kom yooj yim rau kev sib xyaw thiab cov yas ntawm cov yas, thiab txo qis txia thiab thim rov qab.

Txhim kho qhov peev xwm tsim tawm ntawm cov tshuab extruder, L / D loj ntsia hlau muaj qhov muaj peev xwm hloov tau thiab tuaj yeem siv rau kev rho tawm ntawm ntau yam plastics; txawm li cas los xij, thaum L / D loj dhau, cov pa roj hmab yuav raug puas tsuaj los ntawm lub sijhawm cua sov thiab lub hau ntswj Thaum qhov hnyav nws tus kheej nce, qhov kawg ntawm cov flexes thiab sag, uas yooj yim ua rau cov khoom tawg yooj yim ntawm cov ntsia hlau thiab cov ntsia hlau, thiab ua rau cov txheej txheem tsim khoom nyuaj; lub zog siv ntawm lub extruder yog nce. Tus ntsia hlau uas yog luv heev yuav ua rau tsis zoo plasticization ntawm lub kneading.

Ib nrab ntawm qhov sib txawv ntawm txoj kab uas hla sab hauv ntawm txoj kab thiab txoj kab uas hla ntawm lub hau ntswj yog hu ua qhov sib txawv δ, uas tuaj yeem cuam tshuam rau cov khoom lag luam ntawm lub tshuab txuas ntxiv. Raws li δ nce, cov khoom lag luam poob qis. Feem ntau, cov tswj δ nyiam dua li 0.1 txog 0.6 hli. δ tseem me me, cov khoom tso rau qhov loj shearing nyhuv, uas tau txais txiaj ntsig rau kev ua kom yas, tab sis δ me dhau, muaj zog txiav txim siab yooj yim ua rau thermal kho tshuab tsis zoo ntawm cov khoom, thiab tib lub sijhawm, cov ntsia hlau tau yooj yim dai lossis rubbed tiv thaiv phab ntsa ntawm lub tog raj kheej, thiab Thaum δ tseem tsawg dhau, yuav luag tsis muaj qhov to lossis thim rov qab ntawm cov khoom, uas cuam tshuam rau kev sib xyaw ntawm cov yaj mus rau qee yam.

Helix kaum sab xis Φ yog lub kaum sab xis ntawm cov xov thiab seem ntawm cov ntsia hlau. Raws li the nce, qhov khoom lag luam ntawm lub tshuab extruder nce, tab sis cov nyhuv txiab thiab cov nias quab yuam ntawm cov yas yuav txo. Feem ntau, lub kaum sab xis Helix yog nruab nrab ntawm 10 ° thiab 30 degrees. Nruab nrab ntawm °, raws cov kev taw qhia ntawm qhov hloov ntawm qhov ntev ntawm lub hau ntswj, feem ntau siv cov vaj huam sib luag zoo, coj lub suab sib npaug nrog lub taub, tus nqi Φ yog li 17 ° 41 '

Qhov ntau dua qhov cov compression piv, qhov loj dua qhov compression piv uas cov yas tau txais. Thaum qhov zawj yog qhov ntiav, nws tuaj yeem tsim qhov siab shear rau cov yas, uas tau txais txiaj ntsig zoo rau lub tshav kub hloov nruab nrab ntawm cov phab ntsa ntawm lub thoob thiab cov khoom siv. Tshaj siab ntawm cov khoom sib xyaw thiab cov yas ua kom muaj txiaj ntsig, qhov qis dua ntawm kev tsim khoom; ntawm qhov tsis sib xws, qhov zawj yog qhov tob. Qhov xwm txheej yog txawv xwb. Yog li no, cov ntaub ntawv kub-rhiab (xws li polyvinyl chloride) yuav tsum siv nrog cov ntsia hlau sib sib zog nqus; rau cov plastics nrog yaj qis viscosity thiab siab thermal stability (xws li polyamide), qhov tob hau ntswj ntsia hlau yuav tsum tau siv.

1. Kev cais ntawm lub hau ntswj

Thaum cov khoom txav mus rau tom ntej ntawm cov ntsia hlau, nws hla qhov hloov ntawm qhov kub thiab txias, siab, viscosity, thiab lwm yam Cov kev hloov no txawv nyob hauv qhov ntev tag nrho ntawm cov ntsia hlau. Raws li cov yam ntxwv hloov ntawm cov khoom, cov ntsia hlau tuaj yeem muab faib ua ntxiv (xa) cov khoom ntu thiab zaws. Ya thiab homogenization ntu.

1. Peb lub xeev ntawm cov yas thiab cov yas

Plastics muaj ob hom thermosetting thiab thermoplastic. Tom qab cov thermosetting yas uas muaj pwm thiab kho, lawv tsis tuaj yeem ua kom sov thiab yaj. Lub thermoplastic pwm tsab xov xwm tuaj yeem rov kho thiab yaj mus rau lwm cov ntawv.

Raws li kev hloov pauv kub, lub thermoplastic ua rau peb-xeev kev hloov ntawm lub xeev iav, lub xeev siab elastic thiab khov dej xeev. Rov qab hloov pauv nrog qhov kub thiab txias, peb lub xeev tsim cov kev hloov pauv ntau zaus.

a. Cov yam ntxwv sib txawv ntawm cov polymer yaj hauv lub tri-xeev:

Iav lub xeev - yas tshwm raws li cov khoom khov; thermal txav zog yog qhov me me, intermolecular quab yuam yog loj, deformation yog qhov tseem ceeb los ntawm kev deformation ntawm daim ntawv cog lus lub kaum ntse ntse; tom qab sab nraud quab yuam raug tshem tawm, txoj kev deformation yog rov muaj zog sai sai, uas yog txoj haujlwm deformation dav dav.

Highly elastic xeev - yas yog ib yam khoom siv roj hmab; deformation yog pab txhawb los ntawm kev qhia ntawm macromolecular txoj kev mob los ntawm kev taw qhia ntawm ntu, thiab tus nqi deformation yog loj; tom qab lub zog sab nraud tshem tawm, qhov deformation tuaj yeem ua kom rov zoo tab sis lub sijhawm ua haujlwm, uas yog lub siab ywj siab deformation.

Cov nplai ntws los ntawm lub xeev - plastics tshwm li muaj cov roj khov heev; thermal lub zog txuas ntxiv txuas ntxiv qhov sib piv ntu ntawm cov xov lwg me me; deformation yog kev hloov pauv tsis tau thiab yog cov yas deformation

b. Yas ua thiab yas tri-xeev:

Machinable nyob rau hauv lub khob yas. Ncab ua rau hauv lub xeev qhov siab elastic, xws li cov hlau xaim, yeeb nkab extrusion, tshuab moulding thiab thermoforming. Hauv cov dej khov ntws hauv lub xeev, nws tuaj yeem pleev xim, rotomolded thiab txhaj tshuaj pwm.

Thaum twg qhov kub siab tshaj qhov ntawm cov viscous flow state, cov yas yuav thermally decompose, thiab thaum kub qis dua lub xeev lub xeev iav, cov yas yuav embrittled. Thaum lub ntsuas kub yas siab dua li ntawm cov viscous flow state lossis qis dua lub xeev lub xeev, cov thermoplastic feem ua rau muaj kev cuam tshuam loj thiab rhuav tshem, yog li ob thaj chaw kub yuav tsum raug zam thaum kev ua lossis siv cov khoom yas.

Lub qhov rooj thiab lub qhov rai profile yog ua los ntawm PVC hmoov. Yas extruder Gearbox yog dav siv ua qhov rais thiab qhov rooj qhov rooj, nrog rau cov khoom siv dai kom zoo nkauj. Nrog rau kev thev naus laus zis niaj hnub thiab kev tsim qauv zoo, nws muaj cov cuab yeej ntawm qhov tsim muaj peev xwm loj, lub neej ntev thiab yas tshwm sim.

Yas extruder Gearbox yog hom kab ntau lawm yog tsim rau extrusion ntawm PVC yas doos thiab windos profiles thiab ntu txuas lus kev sib txuas lus xa xov, Aluminium-yas puas xa khoom, thiab lwm yam. thiab lwm yam zoo. Cov ntawv qhia PVC tuaj yeem siv rau hauv kev tsim kho vaj tsev thiab hauv tsev lossis chaw ua haujlwm.

Lub tshuab roj thiab cua txias, cua sov

Lub zog thiab cov kabmob yog lubricated nrog cov roj pas dej ua ke thiab txaws. Ntxiv rau txaws lubrication, ZLYJ series nyuaj nto gearbox thiab cov kabmob sab saud tau muab ntxiv rau cov roj twj tso kua mis cov roj txuas rau cov kev ua haujlwm yuam kev lubrication.

Cov roj lubricating qib yog nruab nrab-qib siab lub zog roj N220 lossis lwm qhov roj zoo skating roj nrog viscosity zoo sib xws.

Thaum qhov ntsuas kub ntawm qhov ntsuas cua qis dua 0 ° C, ib qho hluav taws xob cua kub tau ntxiv rau hauv cov roj pas dej kom muab cov roj ua kom sov.

Thaum lub ntsuas huab cua sov siab dua li ntawm 35 ° C, peb lub tuam txhab ua cov kev ntsuas nyiaj tshav kub raws li tus nqi ntsuas kub muab los ntawm tus neeg siv los txiav txim siab seb puas yuav nce cov khoom siv txias txias.

ZLYJ series cylindrical bevel gearbox Hardened gearbox qauv:

Cov lus qhia tshwj xeeb: ZLYJ112, 133, 146, 173, 200, 225, 250, 280, 315, 330, 375, 420, 450; SJY224, 250, 280, 315; ZSYJ315, 375, 395, 420, 450, 560; 6E, 7E, 8E, 9E, 10E, 12E, 15E, JHM thiab lwm yam kev lag luam yas thiab cov roj hmab cov khoom lag luam tshwj xeeb (tuaj yeem kho rau ntau yam uas tsis yog cov qauv loj loj hauv lub thawv).

Ntsia thawv ib leeg Extruder Ib qho ntsia hlau yas extruder rau lub tshuab yas extruder

Hais Txog Qhov Zoo Tshaj Plaws,

Cherry Zhang (Chaw Muag Khoom; Miss.)

NER GROUP CO., Txwv

Yantai Bonway Chaw Tsim Tshuaj Tsim Khoom Co., Ltd.

Tel: + 86-535-6330966

Txawb: + 86-18865558975

www.planetary-gearbox.com

https://twitter.com/gearboxmotor

https://www.facebook.com/sogears1993

Viber / Kab / Whatsapp / Wechat: 008618865558975

E-mail:

Ntxiv: No.5 Wanshoushan Kev Yantai nroog Shandong xeev, Suav

Qhov kev pabcuam zoo tshaj plaws los ntawm peb tus kws tsav tsheb xa mus rau koj lub inbox ncaj qha.

peb pab

Tau Txais

Yantai Bonway Manufacturer Co. Ltd

ANo.160 Changjiang Road, Yantai, Shandong, Suav teb (264006)

T + 86 535 6330966

W + 86 185 63806647