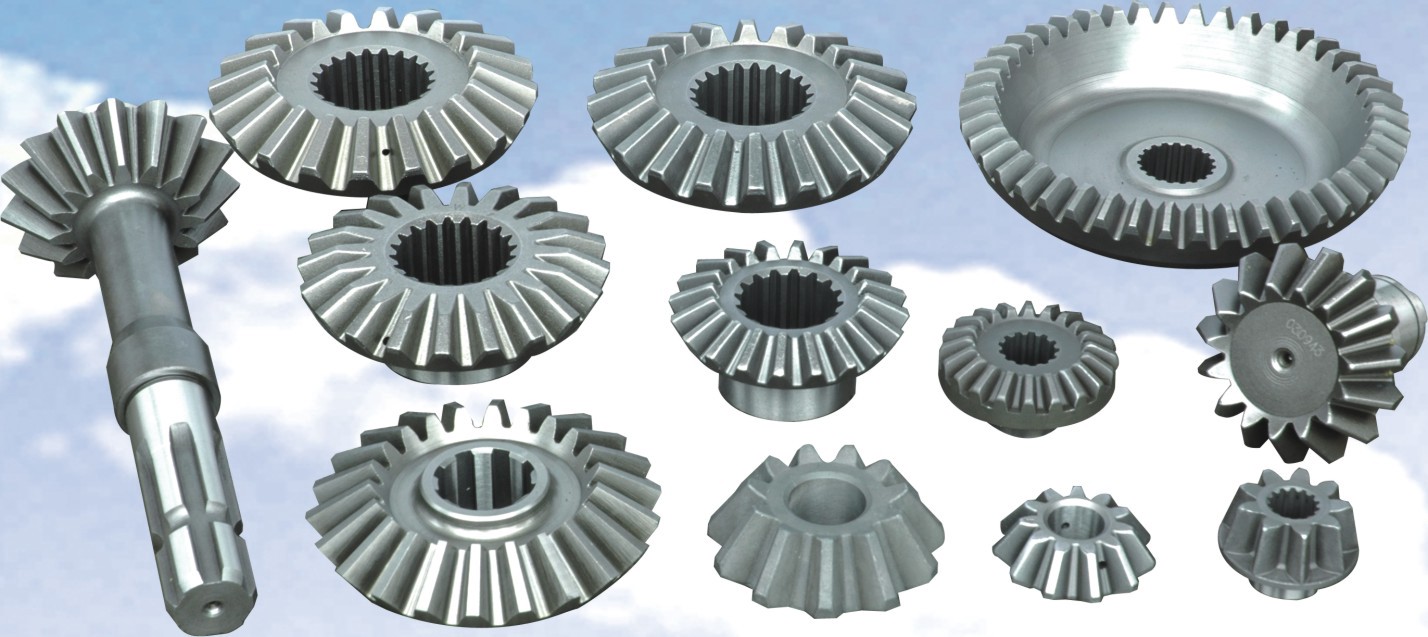

Cov iav bevelled yog siv los xa cov kev txav thiab lub zog nruab nrab ntawm ob txoj kab sib tshuam. Hauv kev siv tshuab dav dav, lub kaum sab xis ntawm cov kev sib tshuam ntawm ob txoj kev sib tw ntawm cov tuav bevelled yog sib npaug li 90 ° (tab sis nws yuav tsis sib npaug li 90 °). Zoo ib yam li cov cylindrical zog, cov iav bevelled muaj indexing cones, addendum cones, hniav hauv paus cones thiab puag cones. Lub khob hliav qab muaj qhov kawg loj thiab me me kawg, thiab lub voj voos sib haum rau qhov loj kawg yog hu ua lub voj voog ntsuas (nws lub vojvoog yog r), lub voj voog ntxiv, lub voj voos hauv paus thiab lub voj voos. Kev txav ntawm kev sib tw ntawm bevelled zog yog sib txig sib luag ntawm cov khub ntawm lub suab nrig rau cov dov ntshiab.

Qhov tsim ntawm tus hniav profile:

Kev tsim cov hniav profile ntawm bevelled zog zoo ib yam li cov qauv ntawm cov cylindrical zog, tshwj tsis yog tias lub hauv paus hlaws yog siv es tsis txhob lub hauv paus kheej kheej. Lub tshuab hluav taws xob nto S tau hloov mus rau lub generatrix ntawm puag puag. Thaum lub tshuab hluav taws xob saum npoo S yog purely dov raws puag ncig lub khob hliav qab, txhua txoj kab ncaj nraim rau ntawm cov pa hluav taws xob hu rau cov generatrix ON ntawm lub hauv paus puag yuav ua rau kev tsis sib haum nkhaus nyob rau hauv qhov chaw. Qhov nkhaus saum npoo no yog cov hniav profile pob ntawm qhov ncaj ntawm cov ncaj bevelled zog. Lub trajectory ntawm txhua tus taw tes rau ntawm txoj kab OK yog tus neeg tsis kam (tus tsis kam ntawm qhov chaw O yog qhov taw tes). Txhua lub ntsiab lus ntawm qhov tsis kam NK yog sib npaug ntawm lub khob O, yog li txoj kev koom tes yuav tsum yog thaj chaw kheej kheej ntawm lub khob O thiab lub voos kheej-kheej yog OK, uas yog, NK yog tus kheej kheej.

kuj:

Cov hniav thiab cov hniav sib tsoo ntawm cov iav bevelled yog txhua qhov kev cog lus, uas yog, lawv tau dav ntawm qhov loj kawg thiab nqaim ntawm qhov me me kawg. Txawm hais tias lub taub hau kev teeb tsa tau tsa rau lub hauv paus caws lub kaum ntse ntse thaum lub sijhawm ua, qhov loj kawg ntawm sab nraud conical sab ntawm cov iav bevelled yog me ntsis siab dua qhov me me kawg, thiab qhov kawg loj tau txiav ntxaum tshaj qhov kawg thaum lub sij hawm milling, thiab qhov dav ntawm cov hniav sib tsoo kuj tseem loj dua qhov kawg loj. Qhov me me kawg me ntsis dav dua, tab sis qhov sib txawv no tsis tuaj yeem ua tau raws li qhov yuav tsum tau ua. Nws yog ib qho tsim nyog yuav tsum tau xaws tawm ntau dua ntawm ob sab ntawm qhov loj kawg. Thaum milling bevelled lub zog ntawm lub tshuab milling, tom qab nruab nrab ntawm cov hniav hniav yog ua tiav rau thawj zaug, cov hniav profile ntawm qhov loj kawg tau tau, tab sis lub qhov dav dav qhov dav tsis tau raws li qhov yuav tsum tau ua. Yog li ntawd, txhua qhov hniav dav dav feem ntau yuav tsum tau milled peb zaug kom ua tiav Lub hom phiaj ntawm milling ntau dua ntawm ob sab ntawm qhov loj kawg hniav hniav, milling lub npoo ntawm ob tog ntawm cov tog hniav bevelled hniav qhov hu ua offset milling. Lub hauv paus ntsiab lus ntawm offset milling yog: ntawm ib sab, cov khoom ua haujlwm yog deflected; ntawm qhov tod tes, lub worktable tau tsiv mus rau qhov ua kom tiav cov hniav sib tsoo me me nrog lub tshuab txiav hniav. Siv cov offset qhov sib txawv ntawm qhov loj kawg thiab qhov kawg me me sib tshuam mus rau cov kev taw qhia pub (hloov chaw) thaum lub haujlwm ua haujlwm tsis zoo, cov nyiaj pub rau milling yog maj mam nce los ntawm qhov me me mus rau qhov kawg loj, thiab qhov kawg loj yog ntau milled tseg.

Tam sim no, muaj ntau qhov kev txiav txim siab milling txoj kev thaum milling bevelled zog, tab sis vim yog qhov tsis sib xws ntawm qhov sib piv ntawm lub suab mus rau tus hniav dav (piv txwv li R / b), thiab qhov sib txawv hauv cov tsis xws li lub suab kaum sab xis thiab tus naj npawb ntawm cov hniav, txhua txoj kev tsis tuaj yeem siv rau txhua lub khob. Kev ua cov iav, yog li ntawd, tsuas tuaj yeem xaiv raws li cov kev mob tshwj xeeb thiab raug kho hauv kev txiav txim siab txiav. Feem ntau siv kev sib xyaw ua ke ntawm kev sib hloov thiab sib dhos rau kev txiav.

bevelled zog cov txheej txheem ntau lawm:

1. Ua ntej, siv hobbing lub hauv paus ntsiab lus kom ua rau lub vias machined thiab lub siab xav duav iav rov ua dua tus kwv tij hobbing. Cov cuab yeej yog lub phiaj xwm nrog ob txoj kab txiav ncaj, ntsia rau ntawm tus tuav lub cuab yeej, thiab rov ua haujlwm nrog lub cuab yeej tuav Linear suab.

2. Lub tshuab nqa yog teeb tsa rau ntawm cov txaj ntu mus tsim lub siab xav tuav lub duav. Lub siab xav lub khauj khaum iav viav vias mus rau sab saud thiab hauv qab mus rau sab saum toj ib ncig ntawm nws tus kheej txoj kab axis, thiab cov txheej txheem txheej txheem tau ntsia rau ntawm lub pluaj tseem ceeb ntawm cov thawv iav hauv qab, thiab lub thawv hloov pauv tau txav los ua lub ntsej muag bevel ntawm cov txheej txheem txheej txheem thiab lub vias vias vias vias iav bevel ntsis Coincide, thiab ua rau tus hniav txhawm rau lub kaum pob kom loj mus rau qhov chaw tau hla los ntawm cov cuab yeej taub.

3. Thaum lub sijhawm txiav cov iav, cov menyuam txaj thiab cov tsaj hluav taws xob yuav tsum tau machined feem ua kom muaj kev sib koom tes ua ke nyob ib ncig ntawm lub axis, uas yog, zoo li yog ob txoj hlua khawm bevelled, lub iav kom tau machined yuav raug machined hauv kev teeb tsa no.

4. Lub tshuab kab axis thiab cov kab sib hloov teb txoj kab ntawm cov menyuam txaj sib tshuam ntawm tus taw tes, uas yog qhov chaw nruab nrab ntawm cov cuab yeej tshuab. Cov kev sib nrig sib hloov no ua rau lub phiaj xwm txhawm rau npaj txhawm rau txhawm rau txhawm rau tiv thaiv hniav.

Raws li tus xov tooj thiab cov qauv ntawm qhov chaw ua haujlwm, nws yog txiav txim siab los npaj lub iav nrog ib tus qauv hniav lossis ob chav hniav. Rau ib-thooj me-pob ntau lawm, txoj kev txhuam hniav ib leeg feem ntau siv los npaj cov zog.

Muab kauv bevelled zog muaj cov kis tau zoo, ruaj khov kis sib piv, loj arc sib tshooj coefficient, nqa tau peev xwm, kis tau tus mob ruaj khov, ua haujlwm ruaj khov, qauv qauv, txuag hluav taws xob thiab txuag khoom, qhov chaw txuag, hnav tsis kam, lub neej ntev thiab lub suab qis.

Qhov zoo ntawm kauv bevelled zog (piv nrog ncaj bevelled zog):

1. Ua kom nce qhov sib cuag sib piv, uas yog, nce qhov sib tshooj ntawm qhov sib tshooj, txo qhov cuam tshuam, ruaj khov rau kev xa mus, thiab txo lub suab nrov.

2. Lub load tshwj xeeb siab txo, qhov hnav yog ntau yam, lub peev xwm load ntawm lub iav tau ntxiv raws li, thiab kev pab lub neej ntev.

3. Qhov kis tau tus mob loj tuaj yeem siv tau, thiab tus lej ntawm lub log me me tuaj yeem ua tau li 5 hniav.

4. Lub ntsej muag hniav tuaj yeem ua tau hauv av los txo lub suab nrov, txhim kho thaj chaw sib chwv thiab txhim kho kom hniav zoo nkauj. Qhov tseeb ntawm cov iav sib tsoo tuaj yeem ncav cuag qib 5.

Muab Kauv bevelled zog yog siv dav hauv tshuab luam ntawv, tsheb sib txawv thiab lub qhov dej. Lawv kuj tuaj yeem siv rau hauv thaj chaw, cov nkoj, cov chaw tsim hluav taws xob, cov nroj tsuag steel, cov chaw nres tsheb ciav hlau cov kev kuaj xyuas, thiab lwm yam. Piv nrog hlau iav, cov iav yas yog qhov kev lag luam, muaj lub neej ntev-tiv taus, thiab muaj haujlwm zoo.

Cov yam ntxwv ntawm bevelled zog:

Lub neej ntev, thauj khoom hnyav muaj peev xwm

Tshuaj lom neeg muaj zog thiab kev tiv thaiv corrosion

Suab nrov thiab kev co txo

Lub teeb nyhav thiab cov nqi qis

Yooj yim rau duab, zoo lubricity

Txoj kev kho cov txheej txheem ntawm cov hniav tuab thaum lub sij hawm offset milling:

Tom qab txiav kev txiav rau ob sab ntawm 2 mus rau 3 hniav nrog cov qauv saum toj no, qhov loj thiab me me ntawm cov hniav yuav tsum kuaj xyuas. Yog tias tus nqi ntsuas tus nqi tsis raug raws li tus nqi cim ntawm daim duab lossis suav, koj yuav tsum kho cov nyiaj tig thiab ntsuas them. Lub hauv paus ntsiab lus ntawm kev kho yog:

1. Yog tias qhov loj me me ntawm qhov kawg me me yog qhov tseeb thiab muaj cov npoo rau qhov loj kawg, qhov nyiaj tig (los yog lub kaum sab xis) thiab qhov yuav tsum nce ntxiv kom nce qhov sib txawv kom qhov kawg me me tsis muaj milled.

2. Yog hais tias qhov loj me ntawm qhov loj kawg yog qhov tseeb thiab cov hniav tuab ntawm qhov kawg me me muaj cov npoo, qhov nyiaj tig (los yog lub kaum sab xis) yuav tsum txo kom txo qhov pab txhawb ntau dua. Qhov kawg me me kuj yog milled tseg, thiab qhov kawg loj yog tsis ua tiav.

3. Yog tias ob qho loj kawg thiab qhov kawg me me muaj cov npoo, thiab cov npoo muaj sib npaug, tsuas yog xav kom txo tau cov offset thiaj li hais tias ob qho loj kawg thiab qhov kawg me me yog milled tawm.

4. Yog hais tias qhov loj me ntawm qhov kawg me me muaj tseeb thiab qhov loj me ntawm qhov kawg loj me heev, qhov nyiaj tig (los yog lub kaum sab xis) yuav tsum txo, thiab qhov pab txhawb me me yuav tsum txo kom tsim nyog kom qhov kawg me me ntxiv lawm milled tawm, thiab qhov loj kawg yog txiav tsawg dua li qee qhov qub.

5. Yog hais tias qhov loj me ntawm qhov loj kawg yog qhov tseeb thiab qhov loj me ntawm qhov kawg me me dhau lawm, qhov nyiaj tig (los yog lub kaum sab xis) yuav tsum nce ntxiv, thiab qhov offset yuav tsum tau nce me ntsis, kom qhov kawg me me yog milled tsawg dua li daim tseem. Yog hais tias tus hniav tuab ntawm qhov kawg me me dhau thaum milling qhov nruab nrab zawj, koj yuav tsum tau hloov lub milling cutter lossis ua tshwj xeeb milling cutter rau kev ua haujlwm.

Iav yog hais txog cov khoom siv tshuab nrog cov zog ntawm cov npoo uas txuas yam tsis tu ncua kom txav kev txav thiab muaj zog. Daim ntawv thov cov zog nyob rau hauv kev sib kis tau tshwm sim thaum ntxov. Thaum xaus ntawm lub xyoo pua puv 19, lub hauv paus ntsiab lus ntawm kev txiav txim siab cov tshuab txiav thiab cov cuab yeej siv tshuab tshwj xeeb thiab cov cuab yeej siv uas tau siv cov ntsiab lus no los txiav cov iav pom ib qho tom qab. Nrog rau kev txhim kho ntawm cov khoom lag luam, kev ua haujlwm ntawm cov iav tau yooj yim tau them rau.

Kev faib tawm qauv:

Feem ntau, muaj cov iav hniav, cov hniav hniav, xaus ntsej muag, ntsej muag ib txwm, ntxiv cov voj voos, hniav puag ncig, lub hauv paus hniav, puag ncig, thiab lub voj voos.

Iav hniav

Raug xa mus ua tus hniav, nws yog txhua lub convex ib feem ntawm lub iav uas siv rau meshing. Cov khoom xaum no feem ntau teem nyob rau hauv ib tus qauv radial. Cov hniav ntawm cov iav mating tau nyob rau hauv kev sib cuag, kom cov khoob khoob tuaj yeem ua ntu zus thiab khiav.

Cog Xyoob

Nws yog qhov chaw ntawm ob lub iav uas nyob ib sab ntawm cov iav; lub ntsej muag kawg yog nyob ntawm lub iav loj lossis cov kab uas tsis muaj kab tawg, thiab lub dav hlau txiav mus rau lub axis ntawm cov iav lossis cua nab.

Xaus ntsej muag

Nws yog lub dav hlau ntawm ob qho kawg ntawm lub iav.

Dharma

Yog hais txog lub dav hlau txiav caj dab rau txoj kab hniav ntawm cov iav.

Ntxiv voj voog

Xa mus rau lub voj voog uas qhov taub ntawm cov hniav nyob.

Hniav paus hniav

Xa mus rau ntawm lub voj voog uas hauv qab ntawm qhov zawj muaj nyob.

Vajvoog

Cov kab hluav taws xob tsim txoj kev tsis sib haum yog lub voj voos kheej kheej.

Lub voj voog ntsuas

Nws yog lub voj voos siv ntsuas rau xam cov duab ntsuas qhov ntev ntawm cov iav qhov kawg ntawm lub ntsej muag.

kev faib:

Lub zog ua si tau muab cais raws li cov hniav, lub pob iav, lub ntsej muag ntawm cov hniav, cov hniav uas cov iav qhov chaw nyob, thiab cov qauv txheej txheem.

Cov hniav profile ntawm cov iav muaj suav nrog tus hniav profile profile, lub kaum sab xis, cov hniav siab thiab txav tawm. Kev sib zog tiv thaiv zog yog yooj yim dua rau kev tsim khoom, yog li nyob rau hauv cov cuab yeej tam sim no, kev tsis txaus siab tus account rau qhov feem ntau, thaum cycloid zog thiab arc zog tau siv tsawg.

Hais txog lub kaum sab xis, zog uas muaj lub kaum ntse ntse me me muaj lub zog me dua-cov kabmob nqa tau; Cov zog uas muaj qhov ntsuas lub siab loj muaj qhov siab dua-kev coj tus kheej, tab sis cov thauj ntawm cov kabmob nce nyob rau hauv tib lub zog sib kis, yog li nws tsuas yog siv rau hauv rooj plaub tshwj xeeb. Tus hniav qhov siab ntawm cov iav tau raug tus txheej txheem, thiab tus txheem ntawm cov hniav siab yog feem ntau tau saws. Muaj ntau ntau yam zoo ntawm cov khoom siv tsis zoo, uas tau siv dav hauv ntau yam khoom siv kho tshuab.

Ntxiv mus, cov ceg iav kuj tseem tuaj yeem muab faib ua cov khoob khoob khoob khoob khoob, cov iav bevelled, cov iav uas tsis yog lub cav, cov ntsia khib, thiab cov iav sib zog raws li lawv lub cev; raws li cov duab ntawm cov kab ntawm cov hniav, lawv muaj peev xwm muab faib ua spur zog, Helical zog, herringbone zog, thiab cov kis nkhaus; raws li cov hniav iav Sab saum npoo tau muab faib ua cov zog sab nraud thiab sab hauv lub zog; raws li cov txheej txheem kev tsim tawm, nws muaj peev xwm muab faib ua cov zog cam, txiav cov iav, dov zog, thiab lub zog pov tseg.

Cov txheej txheem tsim cov khoom siv thiab cov txheej txheem kho cua sov ntawm cov iav muaj qhov cuam tshuam zoo rau lub nra-cov kabmob muaj peev xwm thiab qhov loj thiab qhov hnyav ntawm lub iav. Ua ntej xyoo 1950, carbon hlau feem ntau siv rau zog, cov hlau tsis sib haum yog siv nyob rau xyoo 1960, thiab rooj plaub cov hlau tawv tau siv nyob rau xyoo 1970. Raws li kev tawv tawv, hniav saum npoo tuaj yeem faib ua ob hom: tawv hniav ntawm lub ntsej muag thiab tawv tawv hniav.

Lub zog nrog cov hniav muag hniav muaj qhov hnyav thauj khoom-lub peev xwm, tab sis lawv yooj yim dua rau kev tsim khoom thiab muaj qhov ua tau zoo khiav. Lawv feem ntau siv hauv kev siv tshuab dav dav tsis muaj kev txwv nruj rau qhov loj me thiab qhov hnyav, thiab cov khoom lag luam me. Vim tias lub log me me muaj lub nra hnyav ntawm cov kis tau sib zog, txhawm rau ua kom lub neej ua haujlwm ntawm lub zog loj thiab lub zog me me sib npaug, cov tawv tawv ntawm cov hniav ntawm lub log me me feem ntau siab dua lub log loj.

Cov zog hnyav muaj qhov ua kom siab-ua kom cov kabmob. Tom qab cov iav raug txiav lawm, lawv mam li thim, saum npoo av los sis carburized thiab quenched kom qhov nyuaj. Tab sis nyob rau hauv kev kho cua sov, cov iav yuav ua tsis tau pov tseg, yog li tom qab kev kho cua sov, kev sib tsoo, sib tsoo los yog kev txiav zoo yuav tsum tau nqa tawm kom tshem tawm cov kev ua yuam kev los ntawm kev deformation thiab txhim kho qhov tseeb ntawm lub iav.

cov ntaub ntawv uas

Cov hlau niaj hnub siv rau kev ua cov iav yog quenched thiab tempered steel, quenched steel, carburized thiab quenched steel thiab nitrided steel. Lub zog ntawm cam khwb cia steel yog me ntsis qis dua qhov ntawm forged steel, thiab nws yog feem ntau siv rau cov iav loj dua; grey cam khwb cia hlau muaj cov yam ntxwv tsis zoo thiab siv tau rau hauv lub teeb-qhib qhib lub iav xa mus; zas hlau tuaj yeem hloov tau qee qhov hloov steel los ua zog; cov iav yas siv ntau dua Nyob rau hauv qhov chaw uas muaj lub teeb thauj khoom thiab lub suab qis yuav tsum muaj, lub zog kev sib tw feem ntau siv cov iav hlau nrog cov zoo thermal conductivity.

Nyob rau hauv lub neej yav tom ntej, zog raug tsim nyob rau hauv cov kev taw qhia ntawm lub nra hnyav, siab nrawm, siab qhov tseeb thiab siab ceev, thiab siv zog ua haujlwm me me, lub teeb nyob rau hauv qhov hnyav, lub neej ntev thiab kev lag luam thiab txhim khu kev qha.

Kev txhim kho ntawm cov iav kev tshawb fawb thiab kev tsim khoom thev naus laus zis yuav tshawb xyuas ntxiv cov txheej txheem ntawm cov iav hniav puas tsuaj, uas yog lub hauv paus rau kev tsim cov txheej txheem kev ntseeg lub zog txhim kho, thiab lub hauv paus kev ntsuas rau kev txhim kho load-nqa lub peev xwm ntawm cov zog thiab txuas ntxiv lub neej iav kev txhim kho yog sawv cev los ntawm arc hniav profile Cov ntsiab lus hniav tshiab; tshawb nrhiav cov ntaub ntawv iav tshiab thiab cov cuab yeej tawm tshiab rau kev tsim cov iav; tshawb xyuas elastic deformation ntawm cov zog, kev tsim khoom thiab cov teeb meem txhim kho, thiab kev faib tawm ntawm thaj chaw ntsuas kub, thiab hloov kho cov iav hniav txhawm rau txhim kho lub smoothness ntawm cov haujlwm iav. Thaum nce thaj tsam sib tiv tauj ntawm cov iav hniav, yog li txhawm rau txhim kho cov kabmob qhov peev xwm ntawm lub iav.

Kev txhuam, lub hauv paus pib thiab lub tshuab lubrication yog qhov pib ua haujlwm hauv kev tshawb fawb iav. Kev tshawb fawb ntawm elastohydrodynamic lubrication kev tshawb xav, nrov siv kev siv cov roj hluavtaws ua kom zoo thiab tsim nyog ntxiv rau qhov kub siab ntxiv rau cov roj, uas tuaj yeem tsis tsuas txhim kho cov kabmob kev muaj peev xwm ntawm tus hniav nto, tab sis kuj tseem tuaj yeem txhim kho kev sib kis tau.

Qhov txawv nrog hypoid bevelled zog:

Muab Kauv muab cov iav txhuam thiab hypoid bevelled zog yog cov qauv hloov tseem ceeb uas siv hauv tsheb cov leeg kawg. Dab tsi yog qhov txawv ntawm lawv?

Lub ntsiab thiab tsav lub zog tsav sib txuas ntawm ib qho taw tes, thiab lub kaum sab xis ntawm kev sib tshuam tuaj yeem yog txoj kev nyiam, tab sis nyob rau hauv feem ntau cov tsheb tsav axles, lub ntsiab loj rub tawm tus khub siv 90 ° kev teeb tsa ntsug. Vim tias qhov sib tshooj ntawm qhov kawg ntawm lub ntsej muag ntawm cov hniav iav, tsawg kawg yog ob lossis ntau dua ntawm cov iav hniav sib tsoo ntawm cov tib lub sijhawm. Yog li ntawd, cov kauv iav tau khoov tau nqa lub nra hnyav. Ib qho ntxiv, cov hniav iav tsis yog meshed tib lub sijhawm dhau ntawm tag nrho cov hniav ntev, tab sis maj mam meshed Ib qho kawg tau txuas ntxiv mus rau lwm qhov kawg, kom nws ua haujlwm yooj yim, thiab txawm tias thaum muaj kev kub ceev, lub suab nrov thiab kev co yog heev me me.

Lub taus ntawm lub zog tsav tsis sib tshuam tab sis kev sib tshuam hauv qhov chaw, thiab lub kaum sab xis ntawm qhov chaw kuj saws tau 90 ° kaum lub dav hlau sib txawv txoj kev dav hlau. Lub zog tsav tsheb ncej muaj ib qho poob qis / downward offset ntu piv rau cov uas tau tsav lub iav tsav (xa mus rau sab sauv lossis qib qis raws li ntawd). Thaum lub offset tau loj rau ib qho twg, ib lub zog qhia tuaj yeem hla los ntawm lwm lub iav ncej. Nyob rau hauv txoj kev no, compact bearings tuaj yeem raug teeb tsa ntawm ob sab ntawm txhua lub iav, uas tau txais txiaj ntsig zoo los txhim kho cov kev txhawb nqa kom nruj thiab kom ntseeg tau qhov tseeb ntawm lub iav hniav, thiaj li ua kom lub iav muaj sia. Nws yog tsim rau los ntawm-hom tsav axles.

Tsis zoo li cov kauv bevelled zog, qhov twg lub ntsiab thiab tsav lub zog muaj tib lub kaum sab xis tsis sib luag vim tias cov axes ntawm lub iav ob leeg sib tshuam, qhov axis offset ntawm hypoid gear khub ua rau lub helix kaum sab xis ntawm lub zog tsav ntau dua lub helix kaum ntawm tus tsav iav. Yog li no, txawm hais tias qhov qub modulus ntawm hypoid bevelled zog cov khub yog sib npaug, qhov kawg lub ntsej muag lub ntsej muag tsis sib npaug (qhov kawg lub ntsej muag modulus ntawm tsav iav tau loj dua li ntawm lub zog uas tau tsav). Qhov no ua rau lub zog tsav ntawm lub quasi-ob-sided bevelled zog kis tau muaj qhov loj dua txoj kab uas hla thiab lub zog zoo dua thiab kev txhav dua li cov tsav tsheb ntawm qhov muab kauv sib xyaw bevelled zog kis. Ntxiv rau, vim tias qhov loj diam thiab helix lub kaum sab xis ntawm lub zog tsav ntawm hypoid bevelled zog kis, qhov kev sib tiv tauj rau ntawm tus hniav nto yog txo qis thiab kev pab cuam lub neej tau nce.

Txawm li cas los xij, thaum txoj kev xa khoom tseem me me, lub zog tsav ntawm lub quasi-ob-sided bevelled gears qhov kev xa khoom tseem loj dua piv rau kev tsav tsheb ntawm cov kauv bevelled zog. Nyob rau lub sijhawm no, nws yog qhov tsim nyog dua los xaiv cov kauv los ntawm txoj hlua khoob bevelled.

Muab Kauv bevelled zog, uas yog kauv bevelled zog, feem ntau siv rau kev txav thiab lub zog xa xov nruab nrab ntawm ob qhov sib tshuam. Cov hniav ntawm cov iav bevelled tau faib rau saum npoo ntawm lub khob hliav qab, thiab cov hniav profile maj mam poob qis los ntawm qhov loj kawg rau qhov kawg me me.

Introduction:

Cov hniav profile ntawm kauv bevelled zog yog arc-puab, thiab lawv feem ntau yog cone-puab, zoo li lub kaus lub cev, yog li lub npe muab kauv bevelled zog.

Muab Kauv bevelled zog yog qhov kis tau tus mob uas tuaj yeem kis tau zoo thiab muaj suab nrov me me raws li txoj kev sib kis ruaj khov. Nws muaj ntau lub npe nyob hauv ntau thaj tsam. Nws kuj yog hu ua kauv bevelled zog, kauv bevelled zog, kauv bevelled zog, arc bevelled zog, Muab kauv bevelled zog, thiab lwm yam.

nta:

Muab kauv bevelled lub zog muaj cov kis loj, ua haujlwm ruaj khov sib kis, loj arc sib tshooj coefficient, muaj peev xwm nqa tau, ruaj khov thiab du kis, ua haujlwm ruaj khov, compact qauv, txuag hluav taws xob thiab txuag khoom, chaw txuag, hnav tsis kam, lub neej ntev thiab lub suab qis.

Ntawm cov ntau hloov kho tshuab, qhov kis tau tus mob ntawm cov kauv bevelled zog yog qhov siab tshaj plaws, uas muaj txiaj ntsig zoo nyiaj txiag rau ntau hom kev hloov tsheb, tshwj xeeb tshaj yog cov kev sib kis loj. Cov kis khoom siv yuav tsum tau xa lub qub ntsuas yog qhov tsawg tshaj qhov chaw-txuag. Qhov chaw uas yuav tsum muaj rau cov saw hlau kis tau yog me me; txoj kev sib kis ntawm cov kauv bevelled zog yog ruaj khov tas mus li, thiab qhov kis tau tus mob ruaj khov yog feem ntau qhov yuav tsum tau ua kom muaj kev sib kis hauv qhov kev xa mus ntawm ntau yam khoom siv kho tshuab; muab kauv cov hlua khoob ua haujlwm ruaj khov thiab muaj lub neej ntev.

daim ntawv thov:

Muab Kauv bevelled zog tau siv dav hauv cov roj av hauv tsev thiab txawv teb roj av, kev siv tshuab, ntau yam cuab yeej siv tshuab, tshuab ua khoom siv, tshuab ua khoom siv hlau, cov khoom siv hlau, tshuab ua hlau, tsuas tshuab, tshuab ntxhua khaub ncaws, textile machinery, nkoj tsim tshuab, nkoj tsim kev lag luam, aerospace, forklift, elevators, txo hwj chim, dav hlau tsim thiab ntau lwm yam lag luam. Muab Kauv bevelled zog siv nyob rau hauv ntau yam ntawm cov khoom siv kho tshuab, qhia lawv cov kev ua tau zoo, thiab nrov ntawm cov cuab yeej khoom siv aerospace manufacturers, nkoj, chaw tsim khoom tshuab, tshuab ua hlau, cov khoom siv hlau ua cov nroj tsuag, cov hlau ua yob tshuab nroj tsuag, steel rolling machinery nroj tsuag, steel rolling mills, Nws yog xim hlau cog cog cog, cog cov tshuab cog cog, thee cog cov tshuab cog, roj av cog roj av cog tshuab cog, textile machinery cog, tshuab tuam txhab cog khoom, tuam txhab tuam txhab, tuam txhab of elevator, cov tshuab cog cog, cog txo tshuab, cog thee mining cog cog, cog kev lag luam cog tshuab cog, steel dov zeb, hlau dov khoom Hoobkas, metallurgical khoom Hoobkas thiab lwm tus neeg muas zaub.

Thov koj xav tiv tauj peb thiab hauv qab no yog peb tus neeg hu. Peb yuav teb koj sai li sai tau!

Mobile:+ 86-18563806647

Whatsapp / Wechat: 8618563806647

E-mail:

Yantai Bonway Manufacturer Co. Ltd

ANo.160 Changjiang Road, Yantai, Shandong, Suav teb (264006)

T + 86 535 6330966

W + 86 185 63806647